Supply Chain Managers oversee the flow of goods from the supplier to the customer, ensuring products are delivered efficiently and on time. They play a key role in logistics, procurement, and inventory management, balancing cost with quality to meet customer demands.

Skills needed for supply chain management include proficiency in logistics and project management, as well as the ability to solve problems and communicate effectively. These competencies are critical for maintaining the smooth operation of supply chain processes.

Candidates can write these abilities in their resumes, but you can’t verify them without on-the-job Supply Chain Manager skill tests.

In this post, we will explore 7 essential Supply Chain Manager skills, 10 secondary skills and how to assess them so you can make informed hiring decisions.

Table of contents

7 fundamental Supply Chain Manager skills and traits

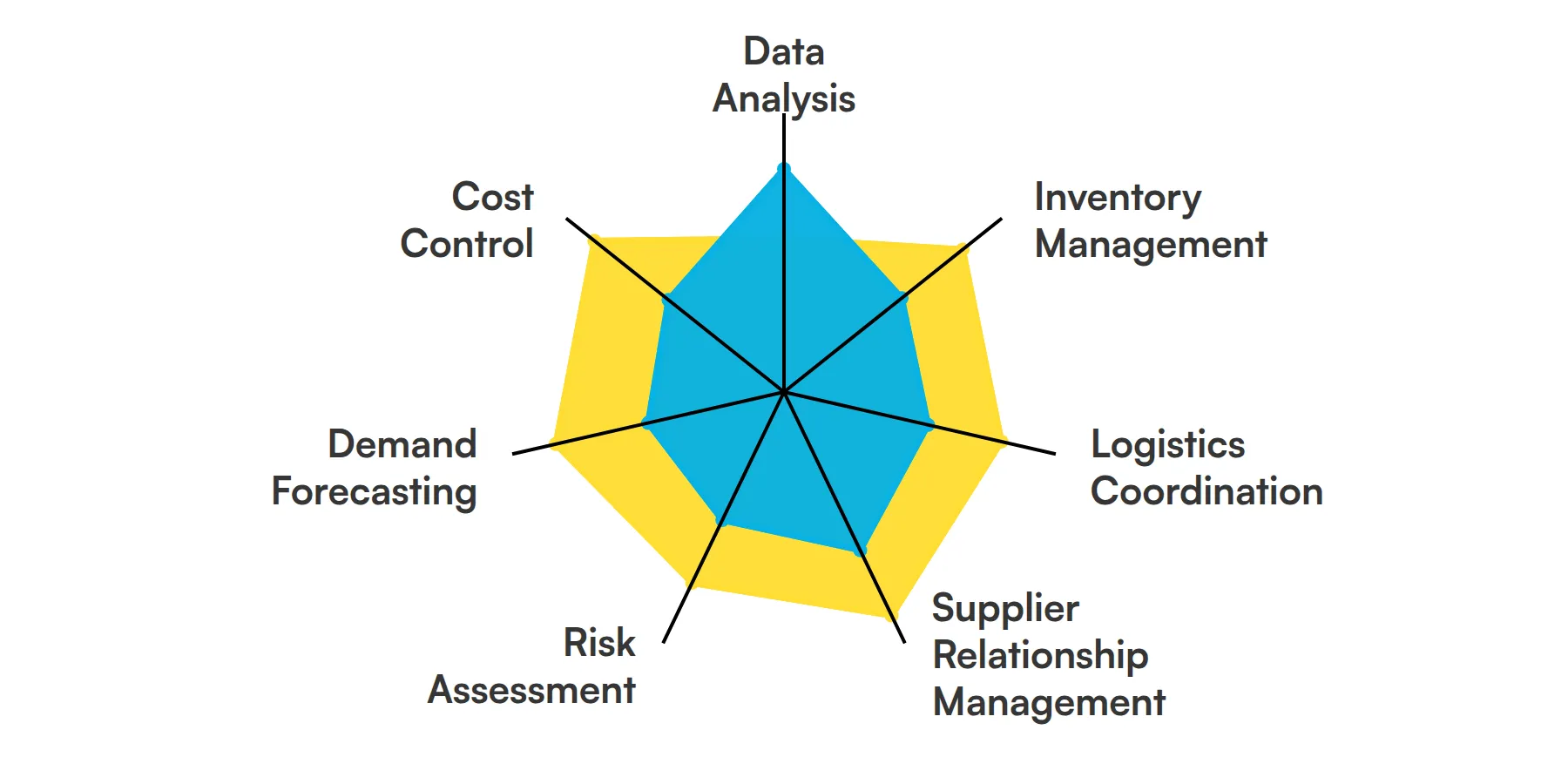

The best skills for Supply Chain Managers include Data Analysis, Inventory Management, Logistics Coordination, Supplier Relationship Management, Risk Assessment, Demand Forecasting and Cost Control.

Let’s dive into the details by examining the 7 essential skills of a Supply Chain Manager.

Data Analysis

Supply Chain Managers need to analyze vast amounts of data to make informed decisions. They use this skill to identify trends, forecast demand, and optimize processes. Accurate analysis helps in minimizing costs and improving supply chain efficiency.

For more insights, check out our guide to writing a Data Analyst Job Description.

Inventory Management

Effective inventory management ensures that the right products are available at the right time without overstocking. It involves monitoring inventory levels and predicting future needs to maintain balance. This skill helps in reducing holding costs and meeting customer demands.

Logistics Coordination

Coordinating logistics involves managing the movement of goods and resources in the supply chain. A Supply Chain Manager uses this skill to ensure timely delivery, optimize routes, and reduce transportation costs. Smooth logistics operations are key to customer satisfaction.

Supplier Relationship Management

Building and maintaining strong relationships with suppliers are critical for a reliable supply chain. This skill involves negotiating contracts, ensuring quality, and managing risks. Positive supplier relationships can lead to better pricing and service.

Risk Assessment

Risk assessment involves identifying potential disruptions in the supply chain and developing strategies to mitigate them. A Supply Chain Manager evaluates risks like supplier failures or natural disasters to safeguard operations. This proactive approach ensures resilience.

Demand Forecasting

Demand forecasting is the ability to predict customer demand with accuracy. This skill utilizes historical data and market analysis to anticipate future needs. Accurate forecasts help in planning production and inventory levels, reducing waste, and enhancing customer satisfaction.

Cost Control

Controlling costs is vital for maintaining profitability in supply chain operations. A Supply Chain Manager uses this skill to identify areas of cost saving by optimizing processes, negotiating better deals, and reducing waste. Effective cost control directly impacts the bottom line.

10 secondary Supply Chain Manager skills and traits

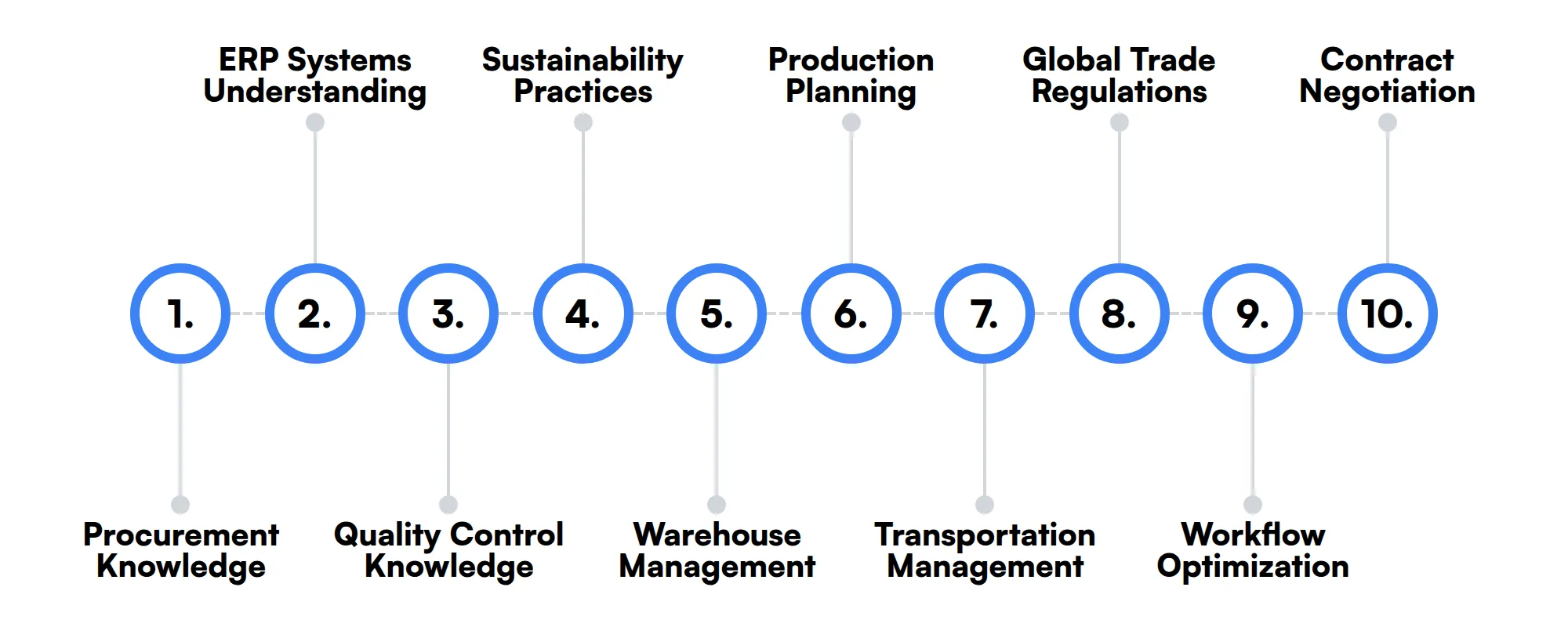

The best skills for Supply Chain Managers include Procurement Knowledge, ERP Systems Understanding, Quality Control Knowledge, Sustainability Practices, Warehouse Management, Production Planning, Transportation Management, Global Trade Regulations, Workflow Optimization and Contract Negotiation.

Let’s dive into the details by examining the 10 secondary skills of a Supply Chain Manager.

Procurement Knowledge

ERP Systems Understanding

Quality Control Knowledge

Sustainability Practices

Warehouse Management

Production Planning

Transportation Management

Global Trade Regulations

Workflow Optimization

Contract Negotiation

How to assess Supply Chain Manager skills and traits

Assessing the skills and traits of a Supply Chain Manager can sometimes feel like piecing together a complex puzzle. With multiple layers like data analysis, inventory management, logistics coordination, and supplier relationship management, it's a task that requires more than just a quick glance at a resume.

While resumes might highlight a candidate's education and experience, they often fail to demonstrate their true proficiency and ability to manage the dynamic challenges of supply chain management. Skills-based assessments go beyond what’s written on paper, helping you understand a candidate's real-world abilities in areas like risk assessment, demand forecasting, and cost control.

To ensure you're hiring the right fit for your supply chain needs, consider incorporating tools like Adaface on-the-job skill tests into your recruitment process. These assessments not only identify the competencies needed but also deliver a more accurate picture of a candidate’s potential, leading to a 2x improvement in the quality of hires.

Let’s look at how to assess Supply Chain Manager skills with these 2 talent assessments.

Data Analysis Test

Our Data Analysis Test assesses a candidate's ability to handle, modify, analyze, and interpret data. It offers insights into a candidate's experience with tasks such as analyzing datasets, detecting anomalies, extracting meaningful insights, and visualizing data using charts and graphs.

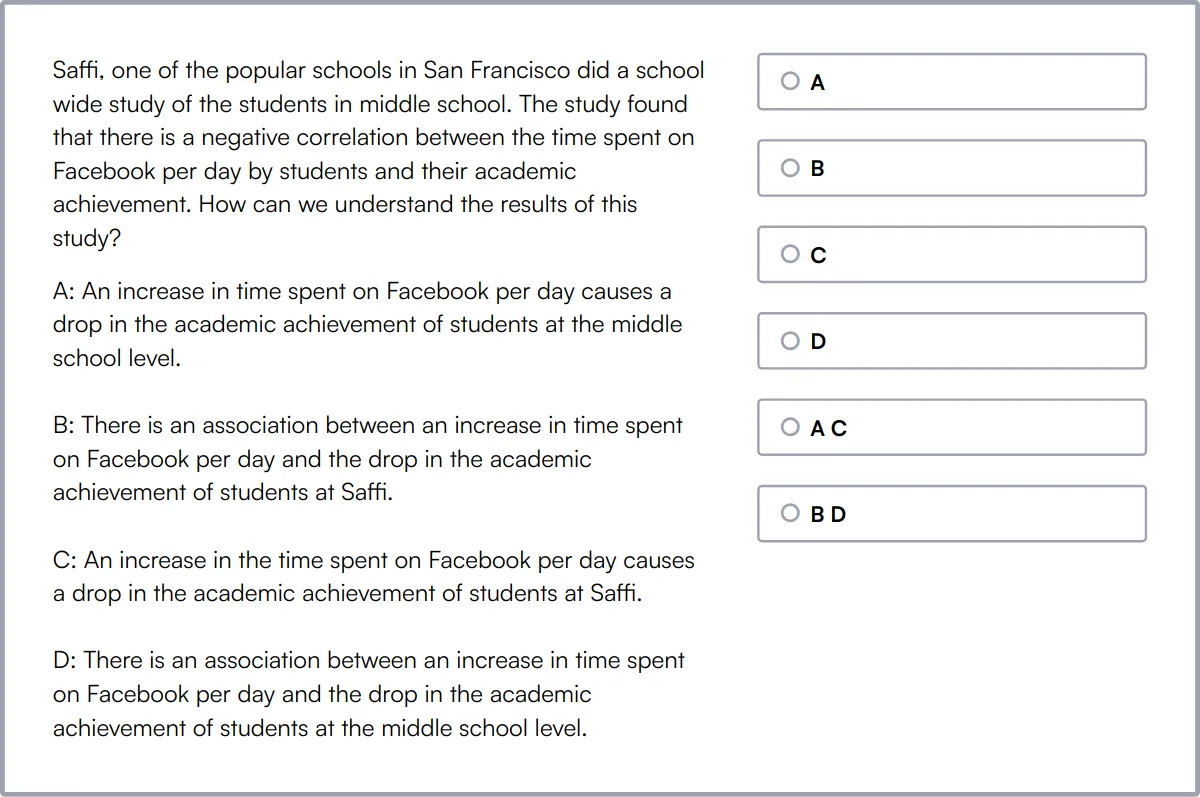

The test evaluates skills in areas such as data modelling, data interpretation, business analysis, and SQL. Candidates must handle scenario-based multiple-choice questions designed to screen for experience in various data operations including making predictions and identifying correlations.

Successful candidates demonstrate proficiency in popular data tools like Excel, showcasing their ability to conduct data investigations, understand business analysis fundamentals, and handle data queries and databases effectively.

Supply Chain Fundamentals Test

The Supply Chain Fundamentals Test evaluates a candidate's understanding of key supply chain concepts. This includes logistics, inventory management, and procurement, using scenario-based multiple-choice questions to assess their ability to manage supply chain operations and technology.

This test explores the candidate’s grasp of areas such as supply chain management basics, logistics, demand planning, and warehouse management. It examines their ability to manage supplier relationships, understand order fulfillment processes, and apply supply chain analytics.

High-scorers show a deep understanding of both risk management and sustainability in supply chains, proving themselves capable of addressing challenges in procurement and supply chain technology. They also demonstrate prowess in supplier relationship management and strategic planning.

Summary: The 7 key Supply Chain Manager skills and how to test for them

| Supply Chain Manager skill | How to assess them |

|---|---|

| 1. Data Analysis | Assess ability to interpret data for informed decision-making. |

| 2. Inventory Management | Evaluate capability to maintain optimal inventory levels and reorder points. |

| 3. Logistics Coordination | Measure skills in orchestrating transportation and delivery schedules. |

| 4. Supplier Relationship Management | Gauge expertise in maintaining positive supplier interactions and negotiations. |

| 5. Risk Assessment | Check proficiency in identifying and mitigating supply chain risks. |

| 6. Demand Forecasting | Examine accuracy in predicting future product demand trends. |

| 7. Cost Control | Determine ability to manage and reduce supply chain expenses. |

Supply Chain Fundamentals Test

Supply Chain Manager skills FAQs

How can a recruiter assess data analysis skills in a Supply Chain Manager?

Review candidates' experience with specific tools like Excel, SQL, or Tableau. Ask about their ability to extract insights from supply chain data, and request examples of past analytics projects.

What questions can help evaluate inventory management skills?

Inquire about their strategies for reducing excess inventory. Ask how they balance stock levels with demand and explore their experience with inventory management systems.

How should logistics coordination skills be assessed?

Discuss their experience in managing transportation and delivery schedules. Evaluation of their decision-making process in route optimization and shipment tracking is also essential.

What strategies are effective for assessing supplier relationship management?

Focus on candidates’ ability to maintain and improve supplier relations. Explore their negotiation skills and history of resolving conflicts with suppliers.

How can you assess a candidate's knowledge of ERP systems?

Ask about their experience with implementing or using ERP software. Discuss how they've utilized ERP systems to improve supply chain processes.

Which questions help evaluate risk assessment capabilities?

Discuss scenarios to understand how they've identified and mitigated potential supply chain risks. Their past experiences during crises can provide valuable insights.

What is the best way to gauge demand forecasting skills?

Ask about tools and methods they've used for predicting demand. Examine how they ensured forecasts align with market trends and actual demand.

Which competencies in transportation management are key to discuss?

Explore their experience with different transportation modes and regulations. Assess their knowledge of cost-saving techniques in transportation management.

40 min skill tests.

No trick questions.

Accurate shortlisting.

We make it easy for you to find the best candidates in your pipeline with a 40 min skills test.

Try for freeRelated posts

Free resources