Hiring supply chain managers can be tricky because you're looking for someone who not only understands logistics but can also juggle many different balls at once. Just like when hiring a warehouse manager, you need to ask the right questions to find the perfect fit.

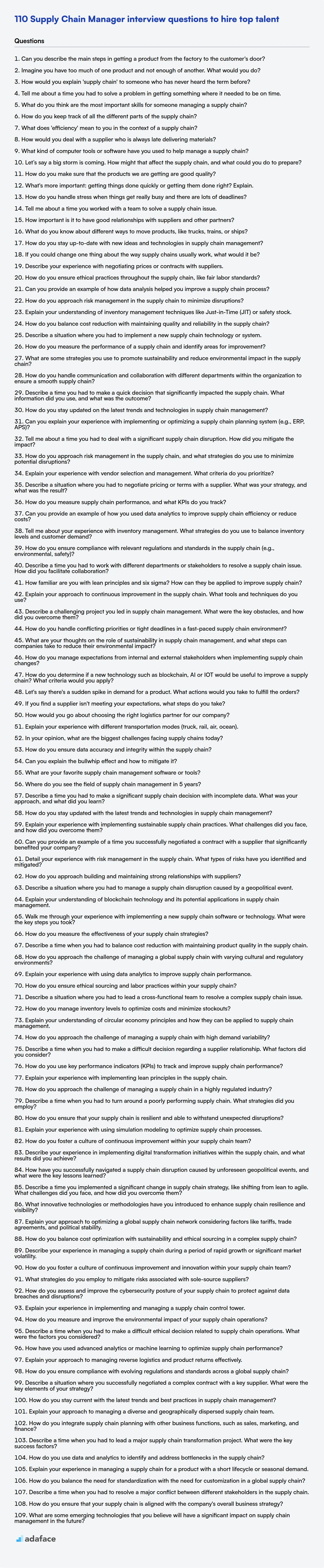

This blog post provides a comprehensive list of interview questions, spanning from basic to expert levels, including multiple-choice questions (MCQs) to assess a candidate's depth of knowledge. We'll cover a range of topics to help you evaluate candidates thoroughly.

By using these questions, you can effectively gauge a candidate's capabilities and potential to excel in a supply chain management role. Before the interviews, consider using Adaface's Supply Chain Fundamentals Test to screen candidates.

Table of contents

Basic Supply Chain Manager interview questions

1. Can you describe the main steps in getting a product from the factory to the customer's door?

The journey of a product from factory to customer involves several key steps. First, manufacturing and production take place, where raw materials are transformed into the finished product. This involves quality control checks throughout the process. Then, the product undergoes packaging and labeling to protect it during transit and provide essential information. Next, warehousing and storage provide a safe haven for products before they are shipped. After that is order processing, where customer orders are received, verified, and prepared for fulfillment. Finally, shipping and delivery involves selecting a carrier, transporting the product, and delivering it to the customer's doorstep, often including last-mile delivery services.

In summary:

- Manufacturing & Production

- Packaging & Labeling

- Warehousing & Storage

- Order Processing

- Shipping & Delivery

2. Imagine you have too much of one product and not enough of another. What would you do?

First, I'd analyze the reasons for the imbalance. Is it a forecasting error, a sudden shift in demand, a supply chain issue, or a pricing problem? Understanding the root cause is critical. Then, I would take several actions:

For the overstocked product, I'd consider promotions, discounts, or bundling it with the understocked product to reduce inventory. I would also explore alternative sales channels or markets. For the understocked product, I'd expedite production, negotiate with suppliers for faster delivery, or consider temporary substitutes to meet demand. Effective communication with sales and marketing is vital to manage customer expectations and potentially shift demand.

3. How would you explain 'supply chain' to someone who has never heard the term before?

Imagine you want a pizza. The supply chain is everything that goes into getting that pizza to you. It starts with the farmer growing the wheat for the crust, the tomato grower, the cheese maker, and so on. Then it includes the transportation of those ingredients to the pizza restaurant, the preparation of the pizza, and finally, delivering it to your door.

Basically, it's the network of all the steps, people, and resources involved in creating and delivering a product or service, from raw materials to the end consumer. It's about how different companies and processes work together to make something happen.

4. Tell me about a time you had to solve a problem in getting something where it needed to be on time.

During my time as a software developer at Acme Corp, we were deploying a critical update to our e-commerce platform. The deadline was set to align with a major marketing campaign launch, and any delay would have a significant financial impact. Three days before the deployment date, we discovered a major bug that affected the payment processing functionality. This meant users couldn't complete purchases.

I immediately took ownership, working with the QA team to isolate the root cause. I quickly diagnosed the issue and developed a patch. However, the standard testing cycle would push the deployment past the deadline. To resolve this quickly, I collaborated with the QA and DevOps teams to create a parallel, expedited testing environment, focusing solely on the patched component and its integration. This allowed us to get the critical fix tested and verified within 24 hours, and we were able to deploy the update on time, ensuring a smooth launch for the marketing campaign.

5. What do you think are the most important skills for someone managing a supply chain?

The most important skills for managing a supply chain effectively revolve around a blend of analytical, interpersonal, and technical abilities. Key among these are strong analytical skills to assess data, identify trends, and optimize processes. Communication and collaboration are crucial for coordinating with various stakeholders, including suppliers, manufacturers, distributors, and customers. Problem-solving skills are essential for addressing disruptions and mitigating risks.

Further important skills would be: Negotiation skills, Risk management, Technical proficiency (understanding of ERP, SCM software). A deep understanding of supply chain principles is also necessary to make informed decisions and improve efficiency. Ultimately, successful supply chain managers are adaptable, proactive, and focused on continuous improvement.

6. How do you keep track of all the different parts of the supply chain?

I keep track of the different parts of the supply chain using a combination of methods, tailored to the specific context. Primarily, I leverage technology like Enterprise Resource Planning (ERP) systems and Supply Chain Management (SCM) software. These systems provide real-time visibility into inventory levels, order status, transportation, and other key aspects.

Beyond software, clear communication and documentation are crucial. This involves establishing strong relationships with suppliers, logistics providers, and internal teams. I rely on regular reporting, performance dashboards, and key performance indicators (KPIs) to monitor progress and identify potential issues. A proactive approach that involves scheduled follow-ups and continuous improvement efforts allows for more effective tracking and management of the supply chain.

7. What does 'efficiency' mean to you in the context of a supply chain?

Efficiency in a supply chain, to me, means maximizing output while minimizing input (resources, time, and cost) across all stages, from sourcing raw materials to delivering the final product to the end customer. It's about doing more with less.

More specifically, it involves optimizing processes, reducing waste (inventory, transportation, defects), streamlining information flow, and leveraging technology to improve coordination and responsiveness. A highly efficient supply chain is agile, cost-effective, and capable of quickly adapting to changing market demands while maintaining high service levels.

8. How would you deal with a supplier who is always late delivering materials?

First, I would try to understand the root cause of the delays. Is it a capacity issue, logistical problems, or something else? I would communicate clearly with the supplier about the impact of the delays on our production schedule and explore potential solutions collaboratively. This could involve adjusting delivery schedules, improving communication, or providing assistance to help them resolve their issues.

If the delays persist despite these efforts, I would need to consider alternative suppliers. This might involve sourcing from a different provider, diversifying our supply chain, or even exploring in-house production if feasible. The goal is to minimize disruptions to our operations and ensure we can meet our commitments.

9. What kind of computer tools or software have you used to help manage a supply chain?

I have used a variety of computer tools and software to manage supply chains. These include Enterprise Resource Planning (ERP) systems like SAP and Oracle, which provide integrated solutions for managing various aspects of the supply chain, from procurement and inventory management to order fulfillment and logistics. I've also worked with Warehouse Management Systems (WMS) such as Manhattan Associates and Blue Yonder to optimize warehouse operations and inventory control.

Beyond these comprehensive systems, I've utilized specialized tools for specific tasks. For example, I've used transportation management systems (TMS) like McLeod LoadMaster for optimizing transportation routes and managing freight costs. Additionally, I have experience with demand planning software, such as those offered by SAS, to improve forecasting accuracy and reduce inventory holding costs. For data analysis and reporting, I commonly use tools like Excel, SQL, and Power BI to monitor key performance indicators (KPIs) and identify areas for improvement within the supply chain. I also have some experience with version control systems like Git for managing configuration changes in the supply chain software deployments.

10. Let’s say a big storm is coming. How might that affect the supply chain, and what could you do to prepare?

A big storm can disrupt the supply chain in several ways. Transportation might be halted due to road closures, flight cancellations, or port shutdowns. This directly impacts the movement of goods from suppliers to manufacturers, and from manufacturers to distributors and retailers. Production can be affected by power outages or raw material shortages, while warehousing and storage facilities may suffer damage, leading to spoilage or loss of inventory.

To prepare, several actions are crucial. Proactive communication with suppliers, distributors, and customers is key to understanding potential disruptions and setting expectations. Increase safety stock levels of critical items to buffer against delays. Diversify transportation routes and consider alternative transportation methods where possible. Review and update business continuity plans, focusing on disaster recovery and supply chain resilience. Ensure data is backed up and accessible in case of system failures. Consider using weather forecasting data in supply chain planning to proactively reroute shipments or adjust production schedules.

11. How do you make sure that the products we are getting are good quality?

Ensuring good product quality involves several stages. First, define clear and measurable quality standards upfront. Then, implement rigorous testing throughout the production process, including:

- Input material inspection: Verifying the quality of raw materials or components.

- In-process checks: Monitoring quality during manufacturing.

- Final product testing: Evaluating finished products against the defined standards.

Finally, implementing a robust feedback loop to continuously improve the quality control process is crucial. This loop should include customer feedback, internal audits, and analysis of defects. Regular calibration and maintenance of testing equipment are also vital.

12. What's more important: getting things done quickly or getting them done right? Explain.

It depends on the context. In a startup environment with limited resources and a need to quickly validate ideas, speed is often more crucial. Getting a minimum viable product (MVP) out the door quickly allows for faster feedback and iteration. This approach emphasizes learning and adapting based on real-world usage. However, in safety-critical systems, such as medical devices or aerospace applications, correctness is paramount. A single bug could have catastrophic consequences.

Ideally, there's a balance. A good approach is to focus on getting the core functionality right from the start, even if it takes a bit longer. Then, iterate quickly on the less critical features. Techniques like automated testing and code reviews can help to ensure a reasonable level of correctness without significantly sacrificing speed. Consider using linting tools and static analysis which will highlight potential issues as you develop code.

13. How do you handle stress when things get really busy and there are lots of deadlines?

When things get busy and deadlines loom, I prioritize tasks using a method like the Eisenhower Matrix (urgent/important). I break down large projects into smaller, more manageable steps. This helps avoid feeling overwhelmed and allows me to focus on completing one thing at a time.

To manage stress directly, I incorporate techniques like taking short breaks to step away from my desk, practicing deep breathing exercises, and ensuring I get enough sleep and exercise outside of work. Clear communication is also key; I proactively update stakeholders on progress and potential roadblocks to avoid surprises and manage expectations.

14. Tell me about a time you worked with a team to solve a supply chain issue.

In my previous role at Acme Corp, we faced a critical shortage of microchips due to unexpected demand surges and factory shutdowns. Our team, comprised of members from procurement, logistics, and manufacturing, collaborated to mitigate the impact. We first prioritized orders based on customer contracts and potential revenue loss.

Then, we explored alternative suppliers, negotiated expedited shipping, and implemented a temporary design modification to use a more readily available chip variant where possible. We communicated daily, tracking progress and adjusting strategies as needed. Ultimately, we minimized production delays and fulfilled 95% of our critical orders, preventing significant financial losses.

15. How important is it to have good relationships with suppliers and other partners?

Maintaining good relationships with suppliers and partners is crucial for several reasons. Strong relationships foster trust and open communication, which can lead to better pricing, preferential treatment, and early access to new products or services. Collaborative partnerships also enable smoother operations, faster problem-solving, and greater flexibility when facing unexpected challenges.

Ultimately, positive relationships contribute to a more reliable supply chain, enhanced innovation, and a competitive advantage. Conversely, strained relationships can result in delays, higher costs, and a negative impact on overall business performance. It helps to mitigate the risk of supply disruption and supports long-term growth.

16. What do you know about different ways to move products, like trucks, trains, or ships?

Different modes of transportation offer distinct advantages for moving products. Trucks provide flexibility and are ideal for last-mile delivery and shorter distances. They can access almost any location but are generally more expensive for long distances than other options. Trains are cost-effective for transporting large volumes of goods over long distances, especially commodities, but require rail infrastructure and have less flexibility in terms of destination. Ships are the most economical way to move extremely large quantities of goods across continents, but are slow and require port infrastructure. The choice depends on factors like distance, volume, cost, speed requirements, and the nature of the goods.

17. How do you stay up-to-date with new ideas and technologies in supply chain management?

I stay current with supply chain management trends through a multi-faceted approach. I regularly read industry publications like Supply Chain Management Review and DC Velocity. I also follow key thought leaders and companies on LinkedIn and Twitter to get insights into emerging technologies and best practices.

Furthermore, I participate in webinars, online courses (like those on Coursera or edX), and industry conferences to deepen my understanding of specific topics like blockchain, AI in supply chain, and sustainable practices. Finally, I occasionally explore open-source supply chain tools (if applicable to the role) on platforms like GitHub to see how they are being developed and used.

18. If you could change one thing about the way supply chains usually work, what would it be?

I would prioritize increasing supply chain visibility and real-time data sharing across all stakeholders. Often, lack of transparency leads to inefficiencies, delays, and increased costs. Enhanced visibility would enable better forecasting, proactive risk management, and faster responses to disruptions. For example, if a supplier is facing a raw material shortage, immediate communication allows downstream partners to adjust production schedules or source alternative materials, minimizing impact. This also fosters better collaboration and trust among all parties involved.

Specifically, I'd push for more widespread adoption of standardized data formats and APIs for seamless information exchange, potentially even leveraging blockchain technology to ensure data integrity and security across the entire chain. This would break down silos and enable a more agile and resilient supply chain.

19. Describe your experience with negotiating prices or contracts with suppliers.

In my previous role, I was responsible for procuring various IT hardware and software licenses. I regularly negotiated pricing with suppliers by researching market rates, leveraging volume discounts based on projected needs, and seeking competitive bids from multiple vendors. A key negotiation involved securing a 15% discount on a new software subscription by highlighting a competitor's offer and emphasizing our long-term partnership potential.

I also have experience reviewing and negotiating contract terms, focusing on aspects like service level agreements (SLAs), payment schedules, and intellectual property rights. For example, when renewing a cloud service contract, I successfully negotiated more favorable SLA terms, ensuring a higher uptime guarantee and faster response times for critical issues.

20. How do you ensure ethical practices throughout the supply chain, like fair labor standards?

Ensuring ethical practices in the supply chain, particularly fair labor standards, involves a multi-faceted approach. Key strategies include conducting thorough risk assessments to identify potential ethical issues within the supply chain, such as child labor or unsafe working conditions. Implementing a robust supplier code of conduct that clearly outlines expectations for ethical behavior and fair labor practices is crucial.

Furthermore, regular audits and inspections of suppliers' facilities help verify compliance with the code of conduct. These audits can be conducted internally or by third-party organizations. Fostering transparency and traceability throughout the supply chain is also important, which allows for better monitoring and accountability. Collaborating with suppliers to provide training and resources on ethical practices can lead to sustainable improvements. Finally, establishing clear mechanisms for reporting and addressing grievances, along with fair remediation processes, is essential.

21. Can you provide an example of how data analysis helped you improve a supply chain process?

In a previous role, we were experiencing frequent stockouts of a critical component used in our manufacturing process. Using data analysis, I examined historical demand data, lead times from suppliers, and inventory levels. The analysis revealed that our forecasting model was underestimating demand during promotional periods and that there was significant variability in supplier lead times that wasn't being accounted for.

Based on these insights, we implemented a new forecasting model that incorporated promotional data and adjusted safety stock levels to buffer against lead time variability. We also negotiated revised lead time agreements with our suppliers. As a result, we reduced stockouts by 30% and improved on-time delivery performance, minimizing disruptions to production.

22. How do you approach risk management in the supply chain to minimize disruptions?

I approach supply chain risk management by first identifying potential disruptions through a comprehensive risk assessment. This includes analyzing historical data, market trends, geopolitical factors, and internal vulnerabilities within the supply chain. Key risks assessed often include supplier financial stability, transportation bottlenecks, natural disasters, and cybersecurity threats.

To mitigate identified risks, I implement several strategies: Diversification (of suppliers and transportation routes), building inventory buffers (strategic safety stock), developing contingency plans (alternative sourcing and production options), and enhancing supply chain visibility (real-time monitoring of key metrics). I also prioritize building strong relationships with suppliers and use contract terms to address potential risks. Regular audits and performance reviews are crucial to monitor the effectiveness of these risk mitigation measures. Furthermore, I would champion the adoption of robust risk management software to provide early warning signs and enable proactive responses to disruptions. Finally, I also consider insurance solutions as another layer of risk mitigation.

23. Explain your understanding of inventory management techniques like Just-in-Time (JIT) or safety stock.

Inventory management techniques aim to optimize the balance between having enough stock to meet demand and minimizing the costs associated with holding inventory. Just-in-Time (JIT) is a system where materials arrive just as they are needed in the production process, minimizing storage costs and waste. It relies heavily on accurate demand forecasting and reliable supply chains.

Safety stock, on the other hand, is extra inventory held to buffer against uncertainties in supply and demand. It helps prevent stockouts if demand is higher than expected or if there are delays in receiving shipments. The level of safety stock is determined by factors such as lead time variability, demand variability, and desired service level.

24. How do you balance cost reduction with maintaining quality and reliability in the supply chain?

Balancing cost reduction with quality and reliability requires a strategic approach. First, identify areas for cost optimization through process improvements, technology adoption (like automation and data analytics), and strategic sourcing. Implement lean principles to eliminate waste and improve efficiency. Negotiate favorable terms with suppliers, but avoid solely focusing on the lowest price, as it can compromise quality.

Second, prioritize quality control and risk management. Invest in robust quality assurance processes, supplier audits, and contingency plans to mitigate disruptions. Diversify the supply base to reduce reliance on single sources. Use data to monitor key performance indicators (KPIs) for both cost and quality, enabling data-driven decisions. Transparency and collaboration with suppliers are crucial for maintaining quality standards while achieving cost efficiencies.

25. Describe a situation where you had to implement a new supply chain technology or system.

In my previous role at a manufacturing company, we implemented a new cloud-based inventory management system to replace our outdated, on-premise solution. The existing system lacked real-time visibility, leading to stockouts and excess inventory. I was part of the team responsible for evaluating different solutions, migrating data, and training users. We chose a system that offered integration with our existing ERP, real-time tracking, and automated reporting.

The implementation involved data cleansing, mapping fields between the old and new systems, and developing custom scripts to handle discrepancies. We also conducted extensive user training sessions to ensure everyone was comfortable using the new system. After go-live, we monitored the system closely and addressed any issues promptly. The new system significantly improved inventory accuracy, reduced stockouts, and provided better visibility into our supply chain. One key benefit was the ability to now predict requirements based on real-time sales order information.

26. How do you measure the performance of a supply chain and identify areas for improvement?

Supply chain performance is measured using key performance indicators (KPIs) across various dimensions. Common metrics include: On-time Delivery (OTD) measuring delivery reliability, Inventory Turnover indicating efficiency in managing inventory, Order Cycle Time representing the time to fulfill an order, Fill Rate showing the ability to meet customer demand from available stock, and Cost of Goods Sold (COGS) reflecting supply chain costs. By tracking these KPIs, we can identify bottlenecks, inefficiencies, and areas where performance lags.

Identifying improvement areas involves analyzing KPI data, conducting root cause analysis, and benchmarking against industry standards or competitors. For example, a low inventory turnover might indicate excess inventory or obsolete stock, prompting improvements in demand forecasting or inventory management practices. Similarly, a high OTD requires review of logistics and production processes. Using tools like process mapping and data analytics can further highlight specific areas where changes can drive significant performance enhancements.

27. What are some strategies you use to promote sustainability and reduce environmental impact in the supply chain?

I focus on several strategies to promote sustainability in the supply chain. First, I prioritize supplier selection based on their environmental practices, looking for certifications like ISO 14001 and evidence of carbon footprint reduction efforts. This includes evaluating their energy consumption, waste management, and water usage. Secondly, I encourage circular economy principles by designing products for durability, repairability, and recyclability. We also explore options for closed-loop supply chains where materials are reused and recycled within the process. Finally, optimizing transportation routes and modes to minimize fuel consumption and emissions, considering consolidation of shipments and utilizing more fuel-efficient vehicles helps a lot.

28. How do you handle communication and collaboration with different departments within the organization to ensure a smooth supply chain?

Effective communication and collaboration across departments are crucial for a smooth supply chain. I achieve this through several strategies. First, I establish clear communication channels, such as regular cross-functional meetings, shared documentation platforms (like wikis or shared drives), and utilizing project management tools. Second, I proactively engage with different departments (e.g., sales, marketing, manufacturing, logistics) to understand their needs and constraints, building relationships based on trust and mutual respect.

Furthermore, I focus on transparency. I share relevant supply chain data and insights with all stakeholders, enabling informed decision-making. If conflicts arise, I facilitate open discussions to identify root causes and implement collaborative solutions. I also emphasize the importance of a shared understanding of the supply chain goals and objectives across all departments.

Intermediate Supply Chain Manager interview questions

1. Describe a time you had to make a quick decision that significantly impacted the supply chain. What information did you use, and what was the outcome?

During a peak season, our primary supplier of packaging materials experienced an unexpected labor strike, threatening to halt our production. I quickly assessed the situation by contacting alternative suppliers, reviewing our current inventory levels, and analyzing demand forecasts. I decided to split our order between two backup suppliers, even though their prices were slightly higher and required expedited shipping, to ensure continuous production.

The outcome was that we maintained near-normal production levels despite the disruption. Although costs increased slightly due to the expedited shipping and higher prices, avoiding a production shutdown preserved key customer relationships and minimized revenue loss. We also diversified our supplier base as a long-term mitigation strategy.

2. How do you stay updated on the latest trends and technologies in supply chain management?

I stay updated on the latest trends and technologies in supply chain management through a variety of methods. I regularly read industry publications like Supply Chain Management Review, Journal of Business Logistics, and relevant articles on platforms like McKinsey and Deloitte. I also subscribe to newsletters and follow key influencers on LinkedIn and Twitter to stay informed about emerging trends and best practices.

Furthermore, I participate in webinars, attend industry conferences such as CSCMP EDGE, and engage in online communities related to supply chain. I actively seek opportunities for continuous learning through online courses and certifications focused on areas like blockchain, AI/ML in supply chain, and advanced analytics, ensuring my knowledge remains current and relevant.

3. Can you explain your experience with implementing or optimizing a supply chain planning system (e.g., ERP, APS)?

In my previous role at Acme Corp, I was part of a team that implemented and later optimized an Advanced Planning System (APS) module within our existing ERP system (SAP S/4HANA). Initially, I was involved in data migration and validation, ensuring the accuracy of master data and transactional data flowing into the APS. This involved working with SQL to query and transform data, as well as collaborating with business stakeholders to resolve data quality issues.

Later, I focused on optimizing the demand planning module. This included fine-tuning forecasting algorithms, implementing ABC analysis for inventory segmentation, and developing custom reports using SAP Analytics Cloud to monitor key performance indicators like forecast accuracy and inventory turnover. I also participated in user training and documentation efforts. The optimization efforts resulted in a 15% reduction in excess inventory and a 10% improvement in forecast accuracy within six months.

4. Tell me about a time you had to deal with a significant supply chain disruption. How did you mitigate the impact?

During the COVID-19 pandemic, our primary microchip supplier experienced a severe production slowdown due to factory closures. This threatened to halt production of our flagship IoT device. To mitigate this, we immediately diversified our supplier base, identifying and qualifying alternative vendors, though this involved rigorous testing and validation of chips from new sources. Simultaneously, our engineering team explored software optimizations to reduce the microchip's processing load, thereby extending the lifespan of existing inventory. We also worked with the sales team to proactively manage customer expectations, communicating potential delays transparently and offering alternative product configurations where possible.

Ultimately, by combining supplier diversification, technical optimizations, and proactive communication, we were able to maintain a reduced but acceptable production level and minimize the negative impact on our customers. We learned the importance of having robust contingency plans and flexibility in our supply chain strategy.

5. How do you approach risk management in the supply chain, and what strategies do you use to minimize potential disruptions?

I approach supply chain risk management by first identifying potential risks through a combination of historical data analysis, industry benchmarking, and collaborative workshops with key stakeholders. These risks can range from supplier failures and geopolitical instability to natural disasters and cybersecurity threats. Once identified, I assess the probability and impact of each risk to prioritize mitigation efforts.

To minimize disruptions, I employ several strategies including: * Diversifying the supplier base to avoid over-reliance on single sources. * Building buffer inventory for critical components. * Implementing robust monitoring systems to detect early warning signs of potential problems. * Developing contingency plans and disaster recovery protocols. * Fostering strong relationships with suppliers to improve communication and collaboration. * Utilizing technology such as blockchain for increased supply chain transparency and traceability.

6. Explain your experience with vendor selection and management. What criteria do you prioritize?

My experience with vendor selection and management involves a structured approach. Initially, I define clear requirements and evaluation criteria in alignment with project goals. I conduct thorough research, seeking recommendations and exploring vendor capabilities. The selection process emphasizes factors such as cost-effectiveness, technical expertise, reliability, security posture (especially crucial), scalability, and alignment with our company culture. I also carefully review SLAs.

Post-selection, I focus on establishing clear communication channels and performance monitoring mechanisms. Regular performance reviews, addressing issues proactively, and maintaining open dialogue are essential for effective vendor management. Contract compliance and managing scope creep are crucial. I also prioritize building strong, collaborative relationships to foster mutual success.

7. Describe a situation where you had to negotiate pricing or terms with a supplier. What was your strategy, and what was the result?

In my previous role, we needed to procure a specific type of sensor for a new product line. The initial quote from our preferred supplier was significantly higher than our budget. My strategy was to first research alternative suppliers to get benchmark pricing. I then approached our preferred supplier with this information, highlighting the cost difference and emphasizing our long-standing relationship.

We negotiated by offering a larger order quantity in exchange for a reduced per-unit price. I also discussed potential compromises on the payment terms, offering faster payment in exchange for a further discount. Ultimately, we reached a mutually agreeable price point that met our budgetary constraints while still allowing the supplier to maintain a reasonable profit margin. The result was a successful product launch within budget.

8. How do you measure supply chain performance, and what KPIs do you track?

I measure supply chain performance by tracking key performance indicators (KPIs) across different areas, including efficiency, effectiveness, and responsiveness. Common KPIs include:

- Order Fill Rate: Percentage of orders fulfilled completely and on time.

- On-Time Delivery (OTD): Percentage of orders delivered on or before the agreed-upon delivery date.

- Inventory Turnover: Measures how efficiently inventory is managed.

- Days of Supply (DOS): Indicates how many days of inventory are available.

- Cash-to-Cash Cycle Time: The time it takes to convert raw materials into cash from sales.

- Supply Chain Cost: Total cost associated with operating the supply chain (transportation, warehousing, etc).

- Perfect Order Rate: Percentage of orders delivered without any issues (damage, errors, delays).

- Forecast Accuracy: How closely demand forecasts match actual demand.

I use these KPIs to identify areas for improvement and optimize supply chain operations.

9. Can you provide an example of how you used data analytics to improve supply chain efficiency or reduce costs?

In a previous role, I analyzed our warehouse inventory data to identify slow-moving items. I used SQL to query our database and Python with pandas to perform statistical analysis (average inventory age, turnover rate). This analysis revealed a significant amount of capital tied up in items with very low demand.

Based on these insights, I collaborated with the procurement team to adjust ordering quantities for these slow-moving items. We implemented a "just-in-time" inventory approach for several of the identified items, which led to a 15% reduction in overall inventory holding costs and freed up valuable warehouse space. We also implemented a system to automatically flag items approaching their expiration date to trigger sales or donations, reducing waste.

10. Tell me about your experience with inventory management. What strategies do you use to balance inventory levels and customer demand?

In my previous role, I actively participated in inventory management processes, primarily focusing on maintaining optimal stock levels to meet customer demand while minimizing holding costs. I used data analysis techniques like historical sales data and forecasting models to predict demand patterns and adjust inventory levels accordingly. I also collaborated closely with the sales and procurement teams to ensure alignment between supply and demand.

My strategies involved implementing ABC analysis to prioritize inventory items based on their value and turnover rate. For high-value items (A items), I focused on tighter control and more frequent monitoring. I also used techniques like safety stock calculations to buffer against unexpected demand fluctuations or supply chain disruptions. To balance inventory and demand, I've used Just-in-Time (JIT) inventory principles where feasible, and Economic Order Quantity (EOQ) to optimize order quantities and reduce overall inventory costs.

11. How do you ensure compliance with relevant regulations and standards in the supply chain (e.g., environmental, safety)?

To ensure compliance with relevant regulations and standards in the supply chain, I would implement a multi-faceted approach. This includes conducting thorough due diligence on suppliers, focusing on certifications (e.g., ISO 14001 for environmental management, ISO 45001 for occupational health and safety), and performing regular audits. Contracts should explicitly outline compliance expectations, including the right to audit and terminate agreements for non-compliance.

Furthermore, a robust monitoring system is essential. This involves tracking key performance indicators (KPIs) related to environmental impact, safety records, and labor practices. I would also establish clear communication channels for reporting potential violations and providing training to suppliers on relevant regulations and standards. Utilizing technology for supply chain mapping and data analytics can further enhance visibility and identify potential risks.

12. Describe a time you had to work with different departments or stakeholders to resolve a supply chain issue. How did you facilitate collaboration?

In a prior role, we faced a critical shortage of a key component used in our flagship product. This threatened to halt production. To resolve it, I brought together representatives from Purchasing, Engineering, Manufacturing, and Sales. I facilitated collaboration by first establishing a common understanding of the problem's impact, using data visualizations showing potential revenue loss and delivery delays. Then, I held a series of focused meetings, each with a clear agenda and defined objectives. Purchasing presented alternative suppliers, Engineering assessed the feasibility of using alternative components, Manufacturing evaluated the impact on the production line, and Sales communicated potential delays to customers.

To ensure alignment, I created a shared document outlining all proposed solutions, their pros and cons, and associated risks. This fostered transparency and allowed stakeholders to provide feedback. We ultimately agreed on a multi-pronged approach: expedited shipping from the current supplier, qualification of an alternative component, and proactive communication with customers. This minimized the disruption and averted a production shutdown. Regular check-ins using project management software kept everyone updated and accountable for their assigned tasks.

13. How familiar are you with lean principles and six sigma? How can they be applied to improve supply chain?

I am familiar with Lean principles and Six Sigma methodologies. Lean focuses on eliminating waste and improving efficiency by streamlining processes and reducing unnecessary steps. Six Sigma aims to reduce variation and defects by using statistical tools to identify and correct the root causes of problems.

In the supply chain, Lean can be applied by implementing just-in-time (JIT) inventory management, reducing lead times through value stream mapping, and optimizing transportation routes. Six Sigma can improve quality control, reduce order fulfillment errors, and optimize forecasting to minimize stockouts or excess inventory. Both methodologies promote continuous improvement by measuring and analyzing performance metrics to identify areas for enhancement.

14. Explain your approach to continuous improvement in the supply chain. What tools and techniques do you use?

My approach to continuous improvement in the supply chain centers around identifying inefficiencies, implementing solutions, and monitoring the results to ensure sustained improvement. I start by analyzing key performance indicators (KPIs) like on-time delivery, inventory turnover, and order cycle time to pinpoint areas needing attention. I then employ tools like Lean principles (e.g., value stream mapping, waste reduction), Six Sigma methodologies (DMAIC), and technology solutions like supply chain visibility platforms to streamline processes and eliminate bottlenecks.

To maintain momentum, I establish feedback loops with stakeholders across the supply chain, regularly reviewing performance data and soliciting input for further enhancements. I use techniques like root cause analysis and Pareto charts to prioritize improvement efforts, focusing on those initiatives that will yield the greatest impact. Furthermore, I actively promote a culture of continuous learning and improvement within the supply chain team, encouraging collaboration and knowledge sharing.

15. Describe a challenging project you led in supply chain management. What were the key obstacles, and how did you overcome them?

In a prior role, I led a project to implement a new warehouse management system (WMS) across three distribution centers. A major obstacle was data migration from the legacy system, which was poorly documented and contained numerous inconsistencies. We overcame this by investing significant time in data cleansing and validation, using SQL scripts to identify and correct errors, and working closely with IT to build custom ETL processes. Another key challenge was user adoption. Many warehouse employees were resistant to change and unfamiliar with the new technology. We addressed this by providing extensive training, creating user-friendly documentation, and establishing a network of 'super-users' who could provide on-the-ground support. Through these efforts, we successfully deployed the WMS on time and within budget, resulting in a 15% improvement in order fulfillment efficiency.

16. How do you handle conflicting priorities or tight deadlines in a fast-paced supply chain environment?

When faced with conflicting priorities and tight deadlines in a fast-paced supply chain, my approach involves a few key steps. First, I immediately assess the urgency and impact of each task. This includes understanding the downstream consequences of delays. Then, I communicate proactively with stakeholders to clarify expectations, negotiate timelines where possible, and identify potential trade-offs. Open communication helps ensure everyone is aligned on the adjusted plan.

Next, I prioritize tasks based on the assessed impact and urgency, focusing on the critical path. I leverage prioritization frameworks like the Eisenhower Matrix (urgent/important) to categorize tasks. I also strive to improve efficiency by identifying opportunities to delegate tasks, automate processes, or eliminate redundancies. If necessary, I escalate potential conflicts to my manager or relevant stakeholders to ensure timely resolution and maintain smooth operations.

17. What are your thoughts on the role of sustainability in supply chain management, and what steps can companies take to reduce their environmental impact?

Sustainability is crucial in supply chain management. It's no longer optional; stakeholders (customers, investors, employees) expect companies to minimize their environmental footprint. A sustainable supply chain enhances brand reputation, reduces risks associated with resource scarcity and regulations, and can even lead to cost savings through improved efficiency.

Companies can take several steps to reduce their environmental impact, including:

- Conducting a supply chain audit: Identify environmental hotspots.

- Adopting circular economy principles: Design products for reuse, repair, and recycling.

- Sourcing sustainable materials: Use recycled or responsibly sourced materials.

- Optimizing transportation: Reduce transportation distances and use more fuel-efficient modes.

- Reducing waste: Minimize waste generation throughout the supply chain.

- Collaborating with suppliers: Encourage suppliers to adopt sustainable practices.

- Investing in technology: Utilize technology to track and manage environmental impact.

18. How do you manage expectations from internal and external stakeholders when implementing supply chain changes?

Managing expectations during supply chain changes requires proactive and transparent communication. For internal stakeholders, clearly define the scope, timelines, and potential impacts of the changes early on. Regular progress updates, highlighting both successes and challenges, are crucial. Using data to illustrate the expected benefits and potential risks helps to ground expectations in reality. For external stakeholders, such as suppliers or customers, it's essential to communicate changes well in advance, explaining the rationale and how it might affect them. Establishing open channels for feedback and addressing concerns promptly fosters trust and collaboration.

Key strategies include:

- Early and Frequent Communication: Keep everyone informed throughout the process.

- Realistic Timelines: Avoid overpromising on delivery dates.

- Transparency: Be open about potential challenges and risks.

- Active Listening: Address concerns and feedback promptly.

- Data-Driven Updates: Use metrics to track progress and manage expectations.

19. How do you determine if a new technology such as blockchain, AI or IOT would be useful to improve a supply chain? What criteria would you apply?

To determine if a new technology like blockchain, AI, or IoT is suitable for improving a supply chain, I'd assess it against several criteria. First, identify specific pain points in the existing supply chain (e.g., lack of transparency, inefficiencies, security vulnerabilities). Then, evaluate whether the technology directly addresses those pain points. For instance, blockchain could enhance transparency and traceability, AI could improve demand forecasting and optimize logistics, and IoT could provide real-time visibility into inventory levels and asset location.

Key criteria include: feasibility (can it be practically implemented?), cost-benefit analysis (do the benefits outweigh the costs?), scalability (can it handle increasing data volumes and complexity?), security (does it enhance or compromise security?), interoperability (can it integrate with existing systems?), and regulatory compliance (does it adhere to relevant regulations?). It's also crucial to consider the availability of skilled resources to implement and maintain the technology, and the readiness of supply chain partners to adopt it. A pilot project or proof-of-concept can help validate the technology's effectiveness before full-scale deployment. The expected ROI must also be quantified.

20. Let's say there's a sudden spike in demand for a product. What actions would you take to fulfill the orders?

First, I'd immediately assess current inventory levels and production capacity. I'd then prioritize orders based on factors like customer loyalty or order size if necessary, communicating transparently with customers about potential delays. To rapidly increase fulfillment, I would explore options like:

- Ramping up production: This might involve overtime for existing staff, additional shifts, or temporarily outsourcing some production.

- Expediting shipments: Explore faster shipping options or negotiate favorable rates with carriers.

- Working with suppliers: Contact suppliers to expedite raw material deliveries or increase order volumes.

- Exploring alternative fulfillment methods: Consider drop-shipping, temporary warehouse space, or partnering with another company to share fulfillment resources.

21. If you find a supplier isn't meeting your expectations, what steps do you take?

First, I'd communicate the specific issues clearly and directly to the supplier, providing data and examples to support my concerns. This includes outlining the impact of their performance on our business. I'd then collaborate with them to develop a mutually agreeable plan for improvement, with specific, measurable, achievable, relevant, and time-bound (SMART) goals.

If the supplier fails to meet the agreed-upon improvement plan, I would escalate the issue internally and explore alternative solutions. This might involve negotiating revised terms, identifying alternative suppliers, or, as a last resort, terminating the relationship. The key is to ensure business continuity and minimize any negative impact on our operations.

22. If you had to reduce supply chain costs by 15%, how would you do it?

To reduce supply chain costs by 15%, I would focus on several key areas. First, I'd aggressively negotiate with suppliers to secure better pricing and payment terms. This could involve consolidating purchasing power, exploring alternative suppliers, or implementing competitive bidding processes. Second, I'd optimize transportation and logistics through route optimization, mode selection (e.g., shifting from air to sea), and warehouse efficiency improvements.

Further savings could be achieved by improving demand forecasting to reduce inventory holding costs and prevent stockouts. This may involve implementing advanced analytics and machine learning techniques. Finally, streamlining processes through automation and technology adoption, such as implementing a supply chain management system or robotic process automation, can reduce labor costs and improve overall efficiency. I would track key metrics to measure progress and ensure cost-saving initiatives are effective.

23. How would you go about choosing the right logistics partner for our company?

- Define needs: Start by clearly defining your company's specific logistics requirements: shipment volume, delivery speed, geographic reach, and any special handling needs (temperature control, hazardous materials, etc.).

- Research and vetting: Research potential partners focusing on their specialization (industry, type of transport), experience, and reputation. Check online reviews, request references, and verify their compliance with relevant regulations.

- Evaluate capabilities and technology: Assess their operational capabilities, technological infrastructure (tracking systems, warehouse management), and ability to integrate with your existing systems. A robust TMS (Transportation Management System) is important for tracking and reporting.

- Cost analysis: Compare pricing models from different providers, considering not just the base rates but also any additional fees (fuel surcharges, accessorial charges).

- Assess customer service: Evaluate the quality of their customer service. Responsiveness, communication, and problem-solving abilities are key.

- Negotiate contract: Secure favorable terms including performance metrics, SLAs (Service Level Agreements), and termination clauses.

24. Explain your experience with different transportation modes (truck, rail, air, ocean).

My experience with transportation modes varies. I have theoretical knowledge of truck, rail, air, and ocean freight operations. I understand that trucking offers flexibility and is often used for last-mile delivery. Rail is typically more cost-effective for long distances, especially for bulk goods. Air freight is the fastest option, suitable for time-sensitive shipments, while ocean freight is generally the most economical for large volumes traveling long distances.

While I don't have practical experience operating or managing these modes, I can analyze data related to them. For example, I can use data to optimize routes, predict transit times based on historical data, and identify potential bottlenecks in the supply chain. I can also assist in evaluating the environmental impacts of different transportation modes, helping to determine the most sustainable option for a given shipment.

25. In your opinion, what are the biggest challenges facing supply chains today?

Supply chains face several significant challenges today. Geopolitical instability, including trade wars and regional conflicts, introduces unpredictability and disrupts established trade routes. Simultaneously, increasing customer expectations for faster, more personalized delivery services put immense pressure on logistics and inventory management.

Furthermore, accurately forecasting demand in a volatile market remains difficult, leading to either costly overstocking or lost sales due to stockouts. Building resilient and adaptable supply chains that can withstand disruptions and meet evolving customer demands is crucial. Addressing sustainability concerns and incorporating ethical sourcing practices also present ongoing challenges, requiring investments in transparency and traceability.

26. How do you ensure data accuracy and integrity within the supply chain?

Ensuring data accuracy and integrity within the supply chain involves several key strategies. First, implement robust data validation processes at each point of data entry, using techniques like format validation, range checks, and cross-referencing against master data. Secondly, utilize blockchain technology to create an immutable and transparent record of transactions across the supply chain. This enhances trust and reduces the risk of data manipulation.

Other strategies include using GS1 standards for product identification and data exchange, implementing robust access controls and audit trails to track data changes, and establishing clear data governance policies. Regular data quality audits and reconciliation processes can also identify and correct discrepancies, improving overall data accuracy and integrity. Utilizing IoT sensors for real-time monitoring and automated data capture can minimize human error.

27. Can you explain the bullwhip effect and how to mitigate it?

The bullwhip effect is a supply chain phenomenon where demand variability increases as you move up the supply chain from the customer towards the supplier. Even small fluctuations in consumer demand can result in large swings in inventory and production levels upstream, leading to inefficiencies like excess inventory, stockouts, and increased costs.

Mitigation strategies include:

- Information Sharing: Sharing point-of-sale (POS) data with suppliers to improve demand forecasting accuracy.

- Vendor Managed Inventory (VMI): Granting suppliers access to inventory data and allowing them to manage inventory levels.

- Order Synchronization: Reducing order batching and promoting smaller, more frequent orders.

- Price Stabilization: Reducing price promotions and discounts that create artificial demand spikes.

- Lead Time Reduction: Shortening lead times to improve responsiveness and reduce the need for large safety stocks.

- Collaboration: Building strong relationships and improving communication with all supply chain partners.

28. What are your favorite supply chain management software or tools?

My favorite supply chain management software and tools often depend on the specific needs of the organization and the industry. However, I generally appreciate tools that offer strong visibility, analytics, and collaboration features. For example, SAP Supply Chain Management stands out due to its comprehensive modules covering everything from planning to execution. Also, I'm impressed with the advancements in cloud-based solutions like Blue Yonder for its AI-powered demand forecasting and optimization capabilities.

For smaller businesses or specific tasks, I find tools like monday.com and Asana useful for project management and task tracking within the supply chain. These help ensure efficient communication and workflow. Another valuable tool is Tableau or Power BI for data visualization and analysis, allowing for better decision-making based on real-time data insights from various points in the supply chain.

29. Where do you see the field of supply chain management in 5 years?

In 5 years, supply chain management will be significantly more resilient, data-driven, and sustainable. We'll see wider adoption of technologies like AI and blockchain for enhanced visibility, predictive analytics, and automated decision-making.

Expect a greater focus on circular economy principles, ethical sourcing, and carbon footprint reduction across the entire supply chain. Companies will prioritize building more agile and adaptable supply networks to better respond to disruptions and evolving customer demands.

Advanced Supply Chain Manager interview questions

1. Describe a time you had to make a significant supply chain decision with incomplete data. What was your approach, and what did you learn?

In a prior role, we faced a sudden surge in demand for a specific component critical to our product. Our inventory system hadn't fully integrated real-time sales data, so we had limited visibility into actual stock levels across all our distribution centers. I had to decide whether to expedite a large, costly shipment from our primary supplier or risk stockouts.

My approach involved gathering all available data – historical sales trends, recent order confirmations, and anecdotal evidence from sales teams. I then created a simple risk assessment matrix, weighing the potential costs of overstocking against the potential revenue loss from stockouts, and used it as a basis to decide to proceed with a smaller, more targeted expedited shipment. I learned the importance of combining quantitative data with qualitative insights and creating contingency plans to address the inherent uncertainty when data is incomplete. The risk assessment was critical. The experience highlighted the need for investing in more accurate, integrated data systems for improved decision-making.

2. How do you stay updated with the latest trends and technologies in supply chain management?

I stay updated through a variety of channels. I regularly read industry publications like Supply Chain Management Review, DC Velocity, and APICS magazine. I also follow relevant blogs and newsletters from thought leaders and consulting firms specializing in supply chain, such as McKinsey, Gartner, and Deloitte. Furthermore, I actively participate in online forums and communities like LinkedIn groups focused on supply chain management and attend webinars and conferences to learn about emerging technologies and best practices directly from experts.

To gain practical knowledge, I explore case studies and research papers published by universities and research institutions. I also experiment with new technologies in personal projects or explore online courses on platforms like Coursera and edX that cover topics like blockchain in supply chains, AI-powered forecasting, and advanced analytics. Keeping an open mind and a continuous learning approach helps me stay current.

3. Explain your experience with implementing sustainable supply chain practices. What challenges did you face, and how did you overcome them?

In my previous role at Acme Corp, I led the initiative to integrate sustainable practices into our supply chain. This involved several key steps: conducting a comprehensive environmental impact assessment of our suppliers, identifying areas for improvement (such as energy consumption, waste generation, and carbon emissions), and working collaboratively with suppliers to implement eco-friendly solutions. For example, we incentivized suppliers to switch to renewable energy sources and adopt closed-loop manufacturing processes. We also implemented a tracking system to monitor the carbon footprint of our transportation logistics.

Some of the main challenges included supplier resistance to change due to increased costs and the complexity of implementing new processes. To overcome this, we provided financial assistance (e.g., grants for equipment upgrades), offered training programs on sustainable practices, and showcased the long-term benefits of sustainability, such as improved brand reputation and reduced operational costs. Additionally, inconsistent data and lack of transparency within the supply chain were initial obstacles. We addressed this by implementing blockchain technology to improve traceability and data accuracy throughout the supply chain network. We also established clear performance metrics and regular audits to ensure compliance and continuous improvement.

4. Can you provide an example of a time you successfully negotiated a contract with a supplier that significantly benefited your company?

During my time at Acme Corp, we were heavily reliant on a specific supplier for a critical component of our main product. Their pricing had been steadily increasing, impacting our profit margins. I took the initiative to renegotiate the contract. After thoroughly researching alternative suppliers and market pricing trends, I presented a compelling case to our existing supplier, highlighting potential cost savings through volume commitments and process improvements on their end. I also emphasized the risk of us switching to a competitor if they couldn't meet our price expectations.

Ultimately, we negotiated a new contract that reduced the component cost by 15% over the next two years. This resulted in significant cost savings for Acme Corp and improved our competitive position. I also secured more favorable payment terms, further boosting our cash flow. The success of this negotiation was due to my proactive research, clear communication of our needs, and willingness to explore alternative solutions.

5. Detail your experience with risk management in the supply chain. What types of risks have you identified and mitigated?

My experience with supply chain risk management includes identifying and mitigating various potential disruptions. I've worked with teams to develop risk assessment frameworks, using both qualitative and quantitative methods. I've identified risks such as supplier bankruptcy, natural disasters impacting key sourcing regions, geopolitical instability affecting transportation routes, and fluctuations in commodity prices. To mitigate these risks, I've implemented strategies like dual-sourcing, building buffer inventory, developing business continuity plans with suppliers, and using hedging instruments to manage price volatility.

Specifically, I've helped design a system that monitors news feeds and social media for early warnings of potential disruptions. For example, when a key supplier was facing financial difficulties, we were able to identify this early on through our monitoring system. This allowed us to quickly qualify and onboard a secondary supplier, ensuring uninterrupted supply. I've also been involved in negotiating contracts with force majeure clauses that protect us in the event of unforeseen circumstances and building out safety stock levels to address unexpected surges in demand.

6. How do you approach building and maintaining strong relationships with suppliers?

Building strong supplier relationships involves open communication and mutual respect. I focus on understanding their business, challenges, and goals to create mutually beneficial arrangements. Regular check-ins, providing constructive feedback, and prompt issue resolution are crucial. Transparent and ethical conduct builds trust.

Maintaining these relationships requires consistent effort. I actively monitor supplier performance against agreed-upon metrics and address any deviations proactively. I look for opportunities for collaboration and innovation, ensuring the supplier is seen as a strategic partner rather than just a vendor. Long-term contracts and fair pricing models further strengthen these ties.

7. Describe a situation where you had to manage a supply chain disruption caused by a geopolitical event.

During my time at a manufacturing company, a new trade embargo was placed on a key supplier in China, disrupting our flow of electronic components. I immediately established communication with alternate suppliers in Taiwan and Vietnam to explore options. We compared lead times, costs, and quality certifications and expedited samples from two potential candidates. Simultaneously, I worked with our engineering team to identify if any component substitutions were possible within our product designs, giving us more flexibility. We ultimately dual-sourced components, mitigating future risk and actually achieving a slight cost reduction through negotiation leveraging the new suppliers.

8. Explain your understanding of blockchain technology and its potential applications in supply chain management.

Blockchain is a distributed, immutable ledger that records transactions across many computers. Instead of a central authority, a network of nodes validates and confirms each transaction, which is then grouped into a block and cryptographically linked to the previous block, forming a chain. This ensures transparency, security, and traceability.

In supply chain management, blockchain can enhance visibility by tracking products from origin to consumer. This can help verify authenticity, reduce counterfeiting, improve efficiency by automating processes like payments and customs clearance using smart contracts, and increase trust among stakeholders. Potential applications include tracking food origins, verifying pharmaceutical authenticity, and managing complex supply networks for industries like electronics.

9. Walk me through your experience with implementing a new supply chain software or technology. What were the key steps you took?

In my previous role, I led the implementation of a new warehouse management system (WMS). The key steps involved first establishing clear goals and requirements through stakeholder interviews and process mapping workshops. This helped define the scope and identify potential challenges early on. Next, we evaluated different WMS vendors based on functionality, scalability, and integration capabilities. We selected a vendor and developed a detailed implementation plan, including data migration, system configuration, user training, and go-live support. We also performed rigorous testing and ran parallel operations to ensure a smooth transition. Post-implementation, we focused on continuous improvement by monitoring system performance, gathering user feedback, and implementing necessary optimizations.

For example, during the data migration phase, we used Python with the pandas library to clean and transform the existing data into the required format for the new WMS. This involved writing scripts to handle data inconsistencies and ensure data integrity. We also created custom reports using SQL to monitor data accuracy and identify any discrepancies during the migration process. Finally, we developed comprehensive training materials, including video tutorials and hands-on exercises, to empower users to effectively utilize the new WMS.

10. How do you measure the effectiveness of your supply chain strategies?

I measure the effectiveness of supply chain strategies using a variety of key performance indicators (KPIs). These metrics provide insights into different aspects of the supply chain's performance, enabling informed decision-making and continuous improvement. Some of the key areas where I use these metrics includes cost, efficiency, reliability, and responsiveness.

Specific examples of KPIs I might track include:

- Total Supply Chain Cost: Measures the overall cost of operating the supply chain.

- Order Fill Rate: Percentage of orders fulfilled completely and on time.

- Inventory Turnover: How efficiently inventory is managed.

- Cash-to-Cash Cycle Time: Time it takes to convert raw materials into cash from sales.

- On-Time Delivery: Percentage of deliveries that arrive on time.

- Perfect Order Percentage: Percentage of orders delivered perfectly (on time, complete, and undamaged).

11. Describe a time when you had to balance cost reduction with maintaining product quality in the supply chain.

In my previous role at a manufacturing company, we faced pressure to reduce costs due to increased competition. One specific area was the sourcing of raw materials for our primary product. The initial proposal was to switch to a cheaper supplier. However, the new supplier's materials had a slightly different composition, potentially impacting the product's durability, which was a key selling point.

To balance cost reduction and quality, I initiated a thorough testing process. We ran simulations and real-world tests using the new materials, comparing the results against our existing quality standards. We also negotiated with the potential new supplier to slightly improve their material composition. Ultimately, we found a balance. By slightly modifying our manufacturing process, and having the supplier tweak the raw materials, we were able to achieve significant cost savings (approximately 15%) without a noticeable decrease in product quality. Regular quality control checks were implemented to monitor for any potential issues.

12. How do you approach the challenge of managing a global supply chain with varying cultural and regulatory environments?

Managing a global supply chain across diverse cultural and regulatory environments requires a multi-faceted approach. Key strategies include thorough due diligence to understand local laws, customs, and business practices in each region. Building strong relationships with local suppliers and partners, emphasizing clear and open communication, and establishing culturally sensitive negotiation strategies are crucial.

Furthermore, technology plays a vital role. Implementing a robust supply chain management system that offers real-time visibility, facilitates data-driven decision-making, and ensures compliance with varying regulations is essential. This includes managing import/export controls, tariffs, and local content requirements. Regularly auditing the supply chain for ethical and sustainable practices is also critical for maintaining a positive brand image and minimizing risks.

13. Explain your experience with using data analytics to improve supply chain performance.

In my previous role, I leveraged data analytics to optimize various aspects of the supply chain. For example, I used time series analysis and forecasting models (specifically ARIMA and Exponential Smoothing) to predict demand for key products. This enabled us to reduce inventory holding costs by 15% and minimize stockouts. I also analyzed transportation data to identify inefficiencies in our logistics network, such as optimizing routes and consolidating shipments, which led to a 10% reduction in transportation expenses.

Furthermore, I built dashboards using tools like Tableau and Power BI to visualize key performance indicators (KPIs) such as on-time delivery, order fulfillment rates, and inventory turnover. These dashboards provided real-time insights, enabling proactive decision-making and identifying areas for improvement. I also used statistical methods to identify root causes of delays or quality issues and developed strategies to mitigate these problems.

14. How do you ensure ethical sourcing and labor practices within your supply chain?

Ensuring ethical sourcing and labor practices involves several key strategies. I would begin by establishing a comprehensive supplier code of conduct that outlines our expectations regarding fair wages, safe working conditions, and environmental responsibility. Regular audits and assessments, both announced and unannounced, would be conducted to monitor supplier compliance. These audits would focus on identifying potential risks such as child labor, forced labor, and unsafe workplace environments.

Furthermore, I would prioritize building strong, collaborative relationships with suppliers, fostering open communication, and providing training and resources to help them improve their practices. This includes investing in traceability systems to track the origin of materials and ensure transparency throughout the supply chain. If non-compliance issues are identified, I would work with suppliers to develop corrective action plans and provide ongoing support to help them achieve compliance. Ultimately, our goal is to promote a culture of ethical and responsible sourcing that benefits both workers and the environment.

15. Describe a situation where you had to lead a cross-functional team to resolve a complex supply chain issue.

I once led a cross-functional team to address a critical shortage of a key component that threatened to halt production. This involved members from procurement, engineering, manufacturing, and logistics. We quickly established a daily stand-up meeting to track progress and identify roadblocks. Procurement explored alternative suppliers and negotiated expedited shipping. Engineering evaluated potential substitute components, considering compatibility and performance. Manufacturing assessed the impact on the production line and adjusted schedules. Logistics coordinated transportation to minimize delays.

Through constant communication and collaboration, we were able to source a suitable alternative component and implement it with minimal disruption. We created a risk mitigation plan for similar situations, including diversifying suppliers and establishing buffer stock levels. This resulted in a significant reduction in future supply chain vulnerabilities.

16. How do you manage inventory levels to optimize costs and minimize stockouts?

I manage inventory levels using a combination of forecasting, safety stock, and inventory management techniques. Forecasting involves analyzing historical sales data, market trends, and promotional activities to predict future demand. Based on the forecast, I determine the optimal order quantities and reorder points. To mitigate the risk of stockouts due to unforeseen demand fluctuations or supply chain disruptions, I maintain a safety stock level.

Specifically, I use techniques like Economic Order Quantity (EOQ) to minimize total inventory costs (holding and ordering costs). I also implement ABC analysis to prioritize inventory management efforts based on the value of items. Regularly reviewing and adjusting inventory parameters based on actual performance and changing market conditions is crucial. Cycle counting helps ensure inventory accuracy, which leads to better planning and fewer stockouts.

17. Explain your understanding of circular economy principles and how they can be applied to supply chain management.

The circular economy aims to minimize waste and maximize resource utilization by keeping products and materials in use for as long as possible. It contrasts with the traditional linear economy ('take-make-dispose'). Principles include designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.

In supply chain management, circular economy principles can be applied by focusing on product design for durability, repairability, and recyclability. Implementing closed-loop supply chains that recover and reuse materials and components reduces the need for virgin resources. Businesses can also prioritize sourcing from suppliers who embrace circular practices and offer take-back programs for end-of-life products. This creates a more resilient and sustainable supply chain.

18. How do you approach the challenge of managing a supply chain with high demand variability?

Managing a supply chain with high demand variability requires a multi-faceted approach. First, I would focus on improving demand forecasting using statistical methods and machine learning techniques to better anticipate fluctuations. This involves analyzing historical data, market trends, and external factors. Secondly, I would implement flexible sourcing and production strategies, such as utilizing multiple suppliers, building buffer inventory (carefully balancing the costs), and employing postponement techniques to delay product differentiation until closer to the actual demand. Finally, I would invest in real-time visibility across the supply chain using technology to quickly identify and respond to disruptions or changes in demand. I would also look at shortening lead times.

19. Describe a time when you had to make a difficult decision regarding a supplier relationship. What factors did you consider?

In my previous role, we relied heavily on a specific supplier for a critical component in our product. They increased their prices by 30% with little warning, citing rising material costs. This put a significant strain on our budget and threatened our profitability. The difficult decision was whether to absorb the cost, find a new supplier, or renegotiate with the existing supplier.