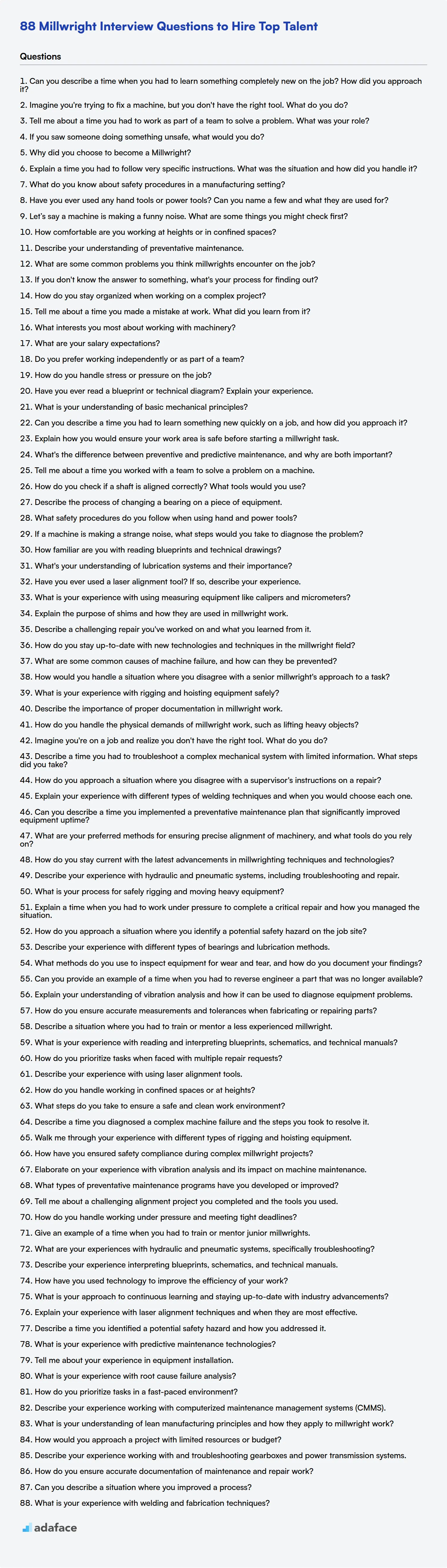

Hiring a skilled millwright requires interviewers to ask questions that uncover practical knowledge and troubleshooting abilities. Understanding these manufacturing specialists can save you time and help find the best fit.

This blog post provides a list of interview questions categorized by experience level, from freshers to experienced candidates, and includes multiple-choice questions (MCQs). It's designed to equip you with the right questions to assess a candidate's skills and experience.

By using these questions, you'll be able to zero in on candidates with the practical and problem-solving skills needed to succeed as a millwright; consider using a Millwright Test beforehand to filter your candidate pool.

Table of contents

Millwright interview questions for freshers

1. Can you describe a time when you had to learn something completely new on the job? How did you approach it?

In my previous role, I was tasked with integrating a new payment gateway that used a completely different API structure than what I was used to. I started by thoroughly reviewing the API documentation, focusing on authentication, request/response formats, and error handling. I then set up a local development environment and began writing small test scripts using curl and Postman to understand the API endpoints and data flow.

Next, I moved on to implementing the integration within our codebase. I broke down the task into smaller, manageable steps, such as creating dedicated functions for making API calls, handling responses, and updating our database. I made sure to add logging and proper error handling. I also consulted with senior engineers on best practices and sought clarification whenever I was unsure about something. I iteratively tested each component until I was confident that the integration was working correctly and reliably.

2. Imagine you're trying to fix a machine, but you don't have the right tool. What do you do?

First, I would try to identify if there is another tool available that could achieve the same result, even if it's not the ideal tool. This might involve some creative problem-solving and thinking outside the box. I'd also check with colleagues or online resources to see if there are known workarounds or alternative methods for the task at hand. If no suitable alternative tool is available immediately, I would assess the urgency of the situation. If it's not urgent, I would prioritize obtaining the correct tool, either by ordering it, borrowing it, or requesting it from the appropriate department. If the situation is urgent, I would explore temporary solutions, such as modifying an existing tool or creating a makeshift tool, while keeping safety as the number one priority.

For example, if I needed a Phillips head screwdriver but only had a flathead, and the screw wasn't too tight, I might carefully try to use the flathead, being mindful not to strip the screw. However, if the risk of damage to the machine or personal injury was high, I would wait for the proper tool, even if it caused a delay.

3. Tell me about a time you had to work as part of a team to solve a problem. What was your role?

During a recent project at my previous company, we were tasked with migrating a legacy database to a new cloud-based system. The existing database was complex and poorly documented, so the migration presented significant challenges. My role was primarily focused on data validation and transformation. I worked with the database administrators to understand the existing data structures and identify any inconsistencies or errors. I then collaborated with the developers to create scripts to cleanse and transform the data to meet the requirements of the new system.

To ensure the accuracy of the migrated data, I also developed a series of automated tests using Python and the pytest framework. These tests compared the data in the old and new systems, highlighting any discrepancies. By working closely with the team, we were able to successfully migrate the database with minimal data loss and downtime. We also created a comprehensive documentation library for the new system.

4. If you saw someone doing something unsafe, what would you do?

My immediate reaction would be to assess the situation to understand the level of danger. If it's something immediately life-threatening, I would directly intervene if safe to do so, like pulling someone away from immediate danger. Otherwise, I would calmly approach the person and explain why their actions are unsafe and suggest a safer alternative.

If the person doesn't respond or the situation is beyond my ability to handle, I would immediately report it to the appropriate authority (e.g., supervisor, safety personnel, or emergency services) providing details like the location, nature of the unsafe act, and individuals involved.

5. Why did you choose to become a Millwright?

I chose to become a Millwright because I enjoy hands-on work, problem-solving, and the satisfaction of keeping complex machinery running smoothly. The blend of mechanical, electrical, and hydraulic systems involved appealed to my aptitude for troubleshooting and repair, and I appreciate the variety of challenges that each day brings.

Moreover, the critical role Millwrights play in maintaining production and ensuring safety resonates with me. I find purpose in contributing to the efficiency and reliability of industrial operations. The opportunity for continuous learning and skill development in a constantly evolving field is also a significant motivator.

6. Explain a time you had to follow very specific instructions. What was the situation and how did you handle it?

In my previous role as a software developer, I was tasked with deploying a critical security patch to our production servers. The instructions were extremely specific and detailed, outlined in a 20-page document covering every step from downloading the patch to verifying its successful implementation. Deviation from these instructions was explicitly forbidden due to the sensitive nature of the security fix and potential for system-wide disruption. I meticulously followed each step, cross-referencing my actions against the documentation at every stage. I documented any minor discrepancies I observed and immediately consulted with the senior engineer for clarification, ensuring I never deviated from the approved procedure.

To ensure adherence, I created a detailed checklist based on the instructions and marked off each step as I completed it. After the patch was deployed, I carefully followed the verification steps, comparing the actual results against the expected results. The successful completion of the deployment without any issues was a direct result of rigorously following the precise instructions and proactively communicating any ambiguities.

7. What do you know about safety procedures in a manufacturing setting?

In a manufacturing setting, safety procedures are crucial for preventing accidents and injuries. They include things like wearing appropriate Personal Protective Equipment (PPE) such as safety glasses, gloves, and hearing protection. Machine guarding is also vital to prevent contact with moving parts. Regular safety training and hazard communication, like understanding SDS (Safety Data Sheets), are essential.

Other important aspects include proper lockout/tagout procedures for equipment maintenance, fire safety protocols, and emergency evacuation plans. Maintaining a clean and organized workspace (housekeeping) also reduces the risk of slips, trips, and falls. Reporting near misses and incidents helps identify and correct potential hazards before they cause harm.

8. Have you ever used any hand tools or power tools? Can you name a few and what they are used for?

Yes, I have used both hand tools and power tools. Examples of hand tools include a hammer (for driving nails), screwdrivers (for tightening or loosening screws), pliers (for gripping and bending), and wrenches (for tightening nuts and bolts).

Power tools I've used include a drill (for making holes), a circular saw (for cutting wood), and a sander (for smoothing surfaces). The specific use varies based on the project, but they generally help perform tasks faster and with less manual effort.

9. Let’s say a machine is making a funny noise. What are some things you might check first?

First, I'd focus on gathering information. I would try to isolate the noise. Is it constant, intermittent, related to a specific operation, or getting worse? Is there any vibration, heat, or smell associated with it? I would also check the machine's recent history - recent maintenance, software updates, or changes in operating conditions that might be related.

Next, I would check the obvious things: power supply stability, connections (loose cables, hoses, etc.), and any easily accessible moving parts for obstructions or wear. Listen closely to determine the location and nature of the sound. Depending on the machine, this could involve checking fans, belts, bearings, pumps, or other mechanical components.

10. How comfortable are you working at heights or in confined spaces?

I am generally comfortable working at heights and in confined spaces, depending on the specific environment and safety measures in place. I understand the potential risks involved and prioritize safety above all else. I follow established protocols and use appropriate safety equipment diligently.

However, if a particular environment presents extreme conditions or feels unsafe, I would communicate my concerns and work collaboratively to find a solution that ensures safety while completing the required tasks. I am open to receiving specific training or familiarization with the environment before starting work.

11. Describe your understanding of preventative maintenance.

Preventative maintenance is a proactive approach to equipment maintenance aimed at preventing failures before they occur. It involves regularly scheduled inspections, adjustments, cleaning, lubrication, and parts replacements based on time, usage, or condition. The goal is to reduce the likelihood of unexpected downtime, extend equipment lifespan, and improve overall operational efficiency.

Essentially, instead of waiting for something to break and then fixing it (reactive maintenance), preventative maintenance follows a schedule to check and maintain equipment. This helps identify and address potential issues early on, reducing the risk of costly repairs and production interruptions. It's like getting regular check-ups for your car to keep it running smoothly.

12. What are some common problems you think millwrights encounter on the job?

Millwrights often face challenges related to precision and working with heavy equipment. Some common problems include:

- Misalignment: Ensuring machinery is perfectly aligned is crucial for optimal performance and longevity, but it can be difficult to achieve and maintain due to factors like settling, vibration, and thermal expansion.

- Equipment Failure: Diagnosing and repairing unexpected breakdowns of complex mechanical systems can be time-sensitive and require specialized knowledge.

- Working in Confined Spaces: Many industrial settings have limited access around machinery, making repairs and maintenance physically demanding.

- Safety Hazards: Working with heavy machinery, power tools, and potentially hazardous materials always presents safety risks that require constant vigilance.

13. If you don't know the answer to something, what's your process for finding out?

When faced with something I don't know, my first step is to clearly define what I don't know. Pinpointing the specific knowledge gap helps focus my research. Next, I leverage a combination of resources depending on the nature of the problem. For programming-related questions, I'll often start with official documentation, Stack Overflow, and relevant blog posts or articles. For other topics, I might consult internal wikis, search engines, or reach out to subject matter experts within my team or network.

Finally, I synthesize the information I gather, test out solutions if applicable, and document my findings for future reference. This documentation might include code comments, notes in my personal knowledge base, or even contributing back to internal knowledge repositories to help others in the future.

14. How do you stay organized when working on a complex project?

When working on complex projects, I prioritize staying organized through a combination of tools and processes. I start by breaking down the project into smaller, manageable tasks and sub-tasks using a task management system like Jira or Trello. I then set realistic deadlines for each task and use a calendar (e.g., Google Calendar) to schedule time for focused work.

I use version control systems like Git for code management, committing changes frequently with descriptive commit messages. Furthermore, I document my code and the project's overall architecture using tools like Markdown or Sphinx. Regular communication and collaboration with the team are crucial, using platforms like Slack or Microsoft Teams to discuss progress, challenges, and potential roadblocks. I regularly review and adjust my plan as needed to ensure the project stays on track.

15. Tell me about a time you made a mistake at work. What did you learn from it?

Early in my career, I accidentally deleted a critical database table while trying to optimize performance. I was running a script that I thought was targeting a test environment, but it was pointed at production. The immediate impact was a service outage. I learned several crucial lessons from this: first, always double-check and triple-check the environment before running any script, especially those that modify data. Second, implement better safeguards and confirmations for critical operations. Third, ensure robust backup and recovery procedures are in place. Finally, communicate mistakes immediately and transparently to minimize damage and enable faster resolution. The incident led to the implementation of mandatory code reviews for database changes and improved disaster recovery drills.

I also learned the importance of a blameless post-mortem. Instead of focusing on individual fault, we analyzed the systemic issues that allowed the mistake to happen, leading to improved processes and reduced risk of future errors.

16. What interests you most about working with machinery?

I'm fascinated by the intricate systems and problem-solving involved in working with machinery. Understanding how different components interact to achieve a specific outcome is very appealing. There's a tangible sense of accomplishment that comes from diagnosing issues, implementing repairs, and optimizing performance.

Specifically, I enjoy the blend of mechanical aptitude and analytical thinking required. The challenge of troubleshooting complex problems, whether it's electrical faults or hydraulic failures, and using diagnostic tools to pinpoint the root cause keeps me engaged and constantly learning. The opportunity to contribute to maintaining and improving the efficiency of essential processes is a significant motivator.

17. What are your salary expectations?

I'm still learning about the full scope of the role and its responsibilities. Based on my research of similar positions in this area and my understanding of the market, my salary expectations are in the range of $X to $Y. However, I'm open to discussing this further and finding a number that works for both of us once I have a better understanding of the overall compensation package, including benefits, opportunities for growth, and other perks.

18. Do you prefer working independently or as part of a team?

I am comfortable working both independently and as part of a team, and my preference often depends on the specific project and tasks involved. I value independent work for focused execution and deep problem-solving, where I can take ownership and drive results. I can effectively manage my time, prioritize tasks, and deliver high-quality work with minimal supervision.

However, I also thrive in collaborative environments. I recognize the immense value of diverse perspectives, shared knowledge, and collective problem-solving that teams provide. I enjoy brainstorming, sharing ideas, and contributing my skills to achieve common goals. I am a strong communicator and collaborator, adept at listening, offering constructive feedback, and working effectively with others to reach the best possible outcomes.

19. How do you handle stress or pressure on the job?

I handle stress and pressure by prioritizing tasks, breaking down large projects into smaller, manageable steps, and focusing on one thing at a time. I also find it helpful to communicate openly with my team and manager about deadlines and potential roadblocks, allowing for collaborative problem-solving and realistic expectations. When appropriate, I take short breaks to clear my head and refocus.

20. Have you ever read a blueprint or technical diagram? Explain your experience.

Yes, I have experience reading blueprints and technical diagrams. While I haven't worked directly in fields like architecture or engineering, I've encountered and interpreted technical diagrams extensively in software development, particularly system architecture diagrams, database schemas, and UML diagrams. These diagrams visually represent the structure and relationships within a software system, including components, data flow, and interactions.

For example, when working on a microservices project, I would regularly consult the system architecture diagram to understand how different services interact and depend on each other. I've also used database schemas to understand the data structures and relationships within a database, which is crucial for writing efficient queries and understanding data integrity. These diagrams were essential for understanding complex systems, debugging issues, and communicating effectively with other team members.

21. What is your understanding of basic mechanical principles?

My understanding of basic mechanical principles includes concepts like force, mass, acceleration (Newton's laws of motion), work, energy (potential and kinetic), power, friction, and torque. I also understand simple machines like levers, pulleys, and inclined planes, and how they utilize mechanical advantage to amplify force. Statics (equilibrium of forces) and dynamics (motion) are also core principles.

Furthermore, I'm familiar with material properties like stress, strain, elasticity, and plasticity. This knowledge helps me understand how materials behave under load and how to design structures or mechanisms that can withstand those loads. I also have a basic understanding of thermodynamics, including heat transfer and energy conversion.

Millwright interview questions for juniors

1. Can you describe a time you had to learn something new quickly on a job, and how did you approach it?

In my previous role, I was suddenly assigned to a project involving a new cloud service, AWS Lambda, which I had no prior experience with. The deadline was tight, and I needed to become proficient quickly. My approach was multifaceted. First, I leveraged official AWS documentation and online tutorials to grasp the fundamental concepts and architecture of Lambda functions. Next, I focused on practical application by building a simple 'hello world' Lambda function and gradually increasing its complexity, experimenting with different triggers and integrations.

I also collaborated with a senior engineer on the team who had experience with AWS Lambda. I asked clarifying questions and sought guidance on best practices. Through this combination of self-directed learning and mentorship, I was able to contribute meaningfully to the project within a short timeframe. For example, I implemented a serverless API endpoint using Lambda and API Gateway to process image uploads. aws lambda invoke helped me quickly test and debug the function. This experience highlighted the importance of resourcefulness and collaboration in rapidly acquiring new skills.

2. Explain how you would ensure your work area is safe before starting a millwright task.

Before starting any millwright task, I would first conduct a thorough visual inspection of the work area. This includes checking for any obvious hazards like spills, obstructions, inadequate lighting, or damaged equipment. I'd verify that all safety guards are in place and functioning correctly on any nearby machinery. Also, I would make sure that I have appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots and ensure I have correct tools for the job.

Next, I would perform a more detailed assessment of the specific task at hand. This involves identifying potential hazards associated with the task, such as moving parts, electrical sources, or hazardous materials. I would then implement appropriate safety measures to mitigate these risks. This might include lockout/tagout procedures, using proper lifting techniques, or establishing a safe work perimeter. I'd consult safety data sheets (SDS) if working with unfamiliar materials. Finally, I would communicate any potential hazards or safety concerns to my supervisor and colleagues before commencing work.

3. What's the difference between preventive and predictive maintenance, and why are both important?

Preventive maintenance is schedule-based and aims to prevent failures by performing maintenance at regular intervals (e.g., monthly inspections, annual oil changes). It's based on time or usage, regardless of the actual condition of the equipment. Predictive maintenance, on the other hand, uses condition monitoring techniques (vibration analysis, thermal imaging, oil analysis) to predict when maintenance is needed. It focuses on identifying potential problems before they lead to failures.

Both are important because they address different aspects of reliability. Preventive maintenance provides a baseline level of upkeep, catching wear and tear. Predictive maintenance optimizes maintenance by focusing on the equipment that needs it most, reducing unnecessary maintenance and preventing unexpected downtime. The combination leads to greater reliability and cost savings compared to either approach alone.

4. Tell me about a time you worked with a team to solve a problem on a machine.

During my internship, the automated testing machine began failing intermittently, halting our development pipeline. Our team, composed of myself, two other interns, and a senior engineer, needed to diagnose the root cause quickly. We started by collecting error logs and sensor readings from the machine's control system. I focused on analyzing the network traffic between the machine and the central server, suspecting a potential communication issue.

After comparing error patterns with recent software updates, we identified a newly introduced configuration file that was causing timing conflicts during peak load. To resolve this, I suggested tweaking the configuration parameters related to packet size and timeout values. We implemented the change, monitored the machine's performance over several days, and confirmed that the issue was resolved, significantly improving the stability of our testing pipeline.

5. How do you check if a shaft is aligned correctly? What tools would you use?

Shaft alignment ensures that connected shafts are collinear, minimizing vibration, wear, and energy loss. Several methods and tools can be used to check shaft alignment.

Common methods include:

- Straightedge and Feeler Gauges: A straightedge is placed across the coupling flanges, and feeler gauges measure the gap between the straightedge and the flange at different points. This method is simple but less accurate.

- Dial Indicators: Two dial indicators are mounted, one on each shaft, and rotated simultaneously. Readings are taken at multiple points to determine misalignment. This method is more accurate than straightedge.

- Laser Alignment Systems: These systems use a laser beam to measure the relative positions of the shafts. They are highly accurate and can compensate for thermal growth and machine movement. They provide real-time feedback and alignment corrections.

Tools used:

- Straightedge

- Feeler gauges

- Dial indicator set with mounting hardware (magnetic bases, rods)

- Laser alignment system

6. Describe the process of changing a bearing on a piece of equipment.

Changing a bearing typically involves several steps. First, safely isolate and lock out the equipment to prevent accidental startup. Then, remove any guards or covers to access the bearing. Next, carefully remove any components that are mounted on the shaft. Use appropriate pullers or bearing removal tools to extract the old bearing, ensuring you don't damage the shaft or housing.

After removing the old bearing, clean and inspect the shaft and housing for any damage or wear. If everything is in good condition, install the new bearing, using appropriate tools and techniques to avoid damaging the bearing. Ensure the bearing is properly seated and aligned. Reassemble the equipment, replace any guards or covers, and perform a test run to verify smooth operation and proper bearing function.

7. What safety procedures do you follow when using hand and power tools?

Before using any hand or power tool, I always inspect it for damage, ensuring guards are in place and functional. I wear appropriate PPE, including safety glasses and gloves, and ensure the work area is clear and well-lit. I strictly follow the manufacturer's instructions for safe operation and never modify a tool or use it for a purpose it wasn't designed for.

With power tools, I double-check the power cord for any fraying or damage before plugging it in. I ensure the tool is properly grounded or double-insulated. I maintain a firm grip, keep my hands away from moving parts, and never leave a running tool unattended. If a tool malfunctions, I immediately disconnect it from the power source and report the issue for repair.

8. If a machine is making a strange noise, what steps would you take to diagnose the problem?

First, I'd gather information: What kind of machine is it? When did the noise start? What does it sound like (grinding, squealing, etc.)? Is the machine performing its usual functions? Any recent maintenance or changes?

Next, I'd visually inspect the machine for obvious issues: loose parts, obstructions, leaks, or damage. Then, I'd try to isolate the noise source by carefully listening in different areas. If safe and possible, I'd observe the machine in operation, checking for unusual vibrations or movements. Depending on the machine type, I might check fluid levels, belt tension, or other critical parameters. Finally, based on my observations, I'd consult the machine's documentation or a more experienced technician for further troubleshooting or repairs.

9. How familiar are you with reading blueprints and technical drawings?

I have a working familiarity with reading blueprints and technical drawings. I've encountered them in past projects, particularly when collaborating with engineering and manufacturing teams. I understand standard conventions, symbols, and annotations commonly used to represent components, dimensions, and tolerances.

While I wouldn't consider myself an expert, I'm comfortable interpreting basic drawings and can quickly grasp the essential information needed to understand a design. If I encounter something unfamiliar, I'm always willing to research and learn to improve my comprehension.

10. What's your understanding of lubrication systems and their importance?

Lubrication systems are vital for reducing friction and wear between moving parts in machinery and equipment. They work by introducing a lubricant, typically oil or grease, between surfaces to create a separating film, minimizing direct contact and heat generation. This results in smoother operation, extended component life, and improved energy efficiency.

The importance of lubrication systems is significant. They prevent premature failure of parts due to wear, reduce energy consumption by lowering friction, help dissipate heat, protect against corrosion, and remove contaminants from the system. Without adequate lubrication, machinery would quickly degrade and become unreliable, leading to costly repairs and downtime.

11. Have you ever used a laser alignment tool? If so, describe your experience.

Yes, I have experience using laser alignment tools, specifically a rotary laser level for various construction and installation projects. I've used it to ensure level foundations, align fence posts, and accurately set the grade for drainage. The tool allowed me to quickly establish a precise horizontal plane over a large area, improving efficiency and accuracy compared to traditional spirit levels or string lines.

My process generally involved setting up the laser level on a stable tripod, leveling it according to the manufacturer's instructions, and then using a laser detector mounted on a grade rod to determine the height relative to the laser plane. I've also used the tool's plumb beam feature for vertical alignment tasks. Careful setup and calibration were essential for reliable results, and I always double-checked measurements to avoid errors.

12. What is your experience with using measuring equipment like calipers and micrometers?

I have hands-on experience using both calipers and micrometers for precise measurements. I've used them extensively to verify dimensions of manufactured parts, ensuring they meet specified tolerances. This includes measuring both internal and external dimensions, depths, and thicknesses. I'm familiar with reading both analog and digital versions of these instruments.

Specifically, I've used calipers and micrometers in quality control processes, during machine setup to ensure correct tooling alignment, and also during prototyping to confirm design accuracy. I understand the importance of proper calibration and zeroing techniques to maintain accuracy and repeatability in my measurements.

13. Explain the purpose of shims and how they are used in millwright work.

Shims are thin, often tapered, pieces of material (typically metal, plastic, or wood) used to fill small gaps or spaces between objects. In millwright work, they serve the purpose of achieving precise alignment, leveling, and load distribution when installing or repairing machinery.

Millwrights use shims in various applications, such as aligning motors, pumps, and gearboxes. By inserting shims under machine feet, they can correct for uneven surfaces or compensate for manufacturing tolerances, ensuring that the machinery operates smoothly and efficiently. This precise alignment is crucial for reducing vibration, preventing premature wear and tear, and extending the lifespan of equipment. Using shims allows for very fine adjustments during installations that would otherwise be impossible.

14. Describe a challenging repair you've worked on and what you learned from it.

A challenging repair I encountered involved a complex intermittent electrical fault in an older CNC milling machine. The machine would randomly shut down during operation, displaying a generic overcurrent error. Initially, I focused on the motor drives and power supply, checking voltages and current draws under load. However, the fault remained elusive.

After days of troubleshooting, I discovered the problem was a fractured wire within the machine's internal control cabinet that connected the motor. The fracture was hidden beneath the insulation, only losing contact when the machine vibrated at a certain frequency. This taught me the importance of thorough visual inspection, even of seemingly intact wiring, and to consider environmental factors like vibration when diagnosing intermittent issues. I learned to use a multi-meter to stress test the wires, simulating the movements and stresses of normal operation. This experience reinforced the need for patience, methodical troubleshooting, and considering all possible causes, even the less obvious ones.

15. How do you stay up-to-date with new technologies and techniques in the millwright field?

I stay up-to-date with new technologies and techniques in the millwright field through a combination of industry-specific resources and continuous learning. I regularly read trade publications like Plant Engineering and Maintenance Technology to understand current trends, new equipment, and best practices. I also attend industry conferences and workshops, such as those offered by the Association for Facilities Engineering (AFE), to network with other professionals and learn about the latest advancements.

Furthermore, I leverage online resources like manufacturer websites and online forums dedicated to millwrighting and maintenance. These resources provide access to technical documentation, case studies, and discussions on troubleshooting common issues and implementing new technologies. I also pursue relevant certifications and training programs to enhance my skills and knowledge in specific areas, such as precision alignment or vibration analysis.

16. What are some common causes of machine failure, and how can they be prevented?

Common causes of machine failure include wear and tear, overheating, lubrication issues, contamination, and improper operation. Over time, components degrade due to friction, stress, and environmental factors. Overheating can damage sensitive electronic components or cause mechanical parts to seize. Inadequate or improper lubrication increases friction and accelerates wear. Contamination from dirt, debris, or moisture can also lead to premature failure. Finally, operating a machine outside of its design parameters or neglecting maintenance can significantly reduce its lifespan.

Preventive measures include regular maintenance, proper lubrication, cooling systems, filtration, and operator training. Scheduled inspections and maintenance can identify and address potential problems before they escalate into failures. Using appropriate lubricants and maintaining proper lubrication levels reduces friction and wear. Adequate cooling systems prevent overheating. Filters remove contaminants from fluids and air. Training operators on proper machine operation and maintenance procedures minimizes the risk of human error.

17. How would you handle a situation where you disagree with a senior millwright's approach to a task?

If I disagreed with a senior millwright's approach, I would first ensure I fully understood their reasoning by asking clarifying questions. I'd then respectfully explain my concerns, focusing on the potential risks or inefficiencies of their method, and offer my alternative approach with clear justification, possibly referencing relevant procedures or best practices. It is important to choose a time and place for the conversation that is appropriate and not disruptive.

Ultimately, I recognize their seniority and experience. If, after a respectful discussion, they still prefer their method, I would defer to their decision while still being mindful of safety and procedural guidelines. If I believed the approach posed a significant safety risk, I would escalate my concerns to the appropriate supervisor, clearly articulating the potential hazard and why I believe it warrants further review.

18. What is your experience with rigging and hoisting equipment safely?

I have hands-on experience with various rigging and hoisting equipment, including chain falls, lever hoists, slings (wire rope, synthetic, and chain), and shackles. My experience involves pre-use inspections to ensure equipment is in good working order and within the certified load capacity. I am familiar with different hitch configurations (vertical, choker, basket) and their impact on load capacity, along with calculating load weights and angles to select appropriate rigging.

Furthermore, I strictly adhere to safety protocols, including wearing appropriate PPE, establishing exclusion zones, and using tag lines to control loads. I'm trained in identifying potential hazards like overhead obstructions, unstable loads, and environmental factors (wind, rain). I understand the importance of proper signaling and communication during lifting operations and always prioritize the safety of myself and others.

19. Describe the importance of proper documentation in millwright work.

Proper documentation is critical in millwright work for several reasons. Accurate records of installations, repairs, and maintenance procedures ensure consistency and prevent errors in future tasks. Detailed documentation facilitates troubleshooting, allowing millwrights to quickly identify and address issues based on past experiences and modifications. This includes things such as accurate measurements during installs, torque values during assembly, and lubricant types used in preventative maintenance.

Furthermore, thorough documentation supports regulatory compliance and safety standards. It provides a clear audit trail for inspections and ensures that all work is performed according to established guidelines. This protects both the millwrights and the equipment they maintain, and can be vital for insurance or warranty purposes.

20. How do you handle the physical demands of millwright work, such as lifting heavy objects?

I understand millwright work is physically demanding and involves lifting heavy objects. I prioritize safety by using proper lifting techniques, such as bending my knees, keeping my back straight, and getting help when needed. I also assess the weight of objects beforehand and use equipment like forklifts, hoists, or dollies whenever possible. I maintain good physical conditioning through regular exercise and stretching to prevent injuries.

Furthermore, I communicate openly with my team about any physical limitations I may have and am proactive in finding solutions to mitigate risks. I am also willing to learn and adapt to new techniques and equipment to improve my ability to handle heavy objects safely and efficiently.

21. Imagine you're on a job and realize you don't have the right tool. What do you do?

First, I would assess if the task can be completed, even if less efficiently, with the available tools. I would explore alternative methods or techniques to achieve the desired outcome. If a workaround isn't feasible, I'd immediately inform my supervisor or a colleague about the missing tool, explaining the impact on the task and potential delays. I would then inquire about the possibility of acquiring the correct tool, borrowing it from another team, or finding a suitable substitute. Communication and finding a practical solution are key.

Millwright intermediate interview questions

1. Describe a time you had to troubleshoot a complex mechanical system with limited information. What steps did you take?

In a previous role, I was responsible for maintaining a complex automated packaging line, and one day it suddenly stopped functioning. The only symptom was a general 'system fault' alarm, with no specific error codes available. I started by visually inspecting all components, checking for obvious issues like disconnected wires or damaged parts. I then consulted the system's schematics (which were outdated), to understand the interactions between the different modules. I began isolating sections of the machine, manually testing sensors, actuators, and motors to narrow down the fault.

Through careful observation and methodical testing, I found that a rarely used pneumatic cylinder was jammed due to dried lubricant. This was causing a pressure drop in the system, triggering the general fault alarm. I cleaned and re-lubricated the cylinder, and the packaging line was back up and running within a few hours. This taught me the importance of thoroughness and a structured approach when troubleshooting complex systems, especially when faced with limited information. Even obsolete documentation can be helpful as a starting point.

2. How do you approach a situation where you disagree with a supervisor's instructions on a repair?

If I disagree with a supervisor's instructions, I would first ensure I fully understand their reasoning and the potential consequences of their approach. I would then respectfully explain my concerns, outlining the potential risks or alternative solutions based on my knowledge and experience, using facts and data to support my viewpoint. I would focus on the safety, quality, and efficiency of the repair.

If, after a constructive discussion, my supervisor still prefers their original approach, and the instructions are not unsafe or unethical, I would follow their guidance while carefully documenting my concerns. If the situation presents a safety hazard or violates established procedures, I would escalate the issue to a higher authority within the organization, as per company policy.

3. Explain your experience with different types of welding techniques and when you would choose each one.

I have experience with several welding techniques, including SMAW (Shielded Metal Arc Welding), also known as stick welding, which is versatile for various materials and thicknesses, particularly useful for outdoor or dirty environments due to its tolerance for contaminants. I've also used GMAW (Gas Metal Arc Welding), or MIG welding, which is efficient for production welding on thinner materials because of its continuous wire feed, offering faster welding speeds and cleaner welds. Furthermore, I'm familiar with GTAW (Gas Tungsten Arc Welding), or TIG welding, known for its precision and high-quality welds on materials like aluminum and stainless steel, often chosen when aesthetics and weld integrity are critical.

I would select SMAW for field repairs and thick materials where portability is key. GMAW would be my choice for high-volume production where speed and efficiency are paramount. GTAW would be reserved for applications requiring the highest weld quality and precision, such as aerospace components or when welding dissimilar metals. My choice always depends on material, environment, weld quality needed and the project budget.

4. Can you describe a time you implemented a preventative maintenance plan that significantly improved equipment uptime?

Yes, in my previous role at a manufacturing plant, we were experiencing frequent breakdowns of our automated packaging line, leading to significant downtime. To address this, I implemented a preventative maintenance plan based on historical failure data and manufacturer recommendations. This included:

- Regular inspections: Scheduled visual checks for wear and tear.

- Lubrication schedules: Defined timelines for lubricating moving parts.

- Component replacement: Proactive replacement of parts with limited lifespans.

As a result, we saw a 30% reduction in unplanned downtime within the first six months, significantly improving equipment uptime and production efficiency.

5. What are your preferred methods for ensuring precise alignment of machinery, and what tools do you rely on?

My preferred methods for ensuring precise alignment of machinery include using laser alignment tools, dial indicators, and precision levels. Laser alignment is particularly effective for horizontal and vertical alignment, as well as for addressing issues like soft foot. Dial indicators are essential for checking runout and parallelism, especially when aligning shafts or couplings. Levels are crucial for establishing a horizontal or vertical reference plane.

Specifically, I rely on tools such as laser alignment systems (e.g., those from Fluke or SKF), magnetic-base dial indicator sets, precision levels (spirit levels and electronic levels), and shim kits of varying thicknesses for making fine adjustments. I also document the alignment process and results meticulously.

6. How do you stay current with the latest advancements in millwrighting techniques and technologies?

I stay current by regularly reading trade publications like "Millwright Journal" and industry-specific online forums. I also attend workshops and seminars offered by organizations like the United Brotherhood of Carpenters and Joiners of America, focusing on topics such as precision alignment, vibration analysis, and new coupling technologies.

Furthermore, I actively seek out opportunities to learn from experienced millwrights on the job. Observing their techniques and asking questions provides valuable insights into practical applications of new technologies and best practices. I also research new equipment and techniques through manufacturer websites and online resources.

7. Describe your experience with hydraulic and pneumatic systems, including troubleshooting and repair.

I have hands-on experience with both hydraulic and pneumatic systems through my previous roles. I've worked on systems involving actuators, valves, pumps, and compressors. My experience includes performing routine maintenance like filter replacements and fluid level checks, as well as diagnosing and repairing system malfunctions. I've used diagnostic tools to identify pressure leaks, faulty sensors, and worn components.

Troubleshooting often involved reading schematics to understand system logic and tracing issues back to the source. I have repaired or replaced components such as hydraulic cylinders, pneumatic valves, and pressure regulators. I'm familiar with safety procedures related to working with pressurized systems, including lockout/tagout procedures and proper PPE.

8. What is your process for safely rigging and moving heavy equipment?

My process for safely rigging and moving heavy equipment involves several key steps. First, I always conduct a thorough risk assessment to identify potential hazards and develop a plan to mitigate them. This includes inspecting the equipment to be moved, the rigging gear, and the pathway. I verify the weight and center of gravity of the equipment, and select appropriate rigging based on this information, ensuring it has sufficient capacity and is in good condition. All personnel involved are briefed on the plan, potential hazards, and their roles.

During the move, I ensure constant communication and clear signals are used. We use tag lines to control the load and prevent swinging, and the movement is slow and deliberate. I continuously monitor the rigging and equipment for any signs of stress or instability. After the move, the rigging is inspected and stored properly. I also document the process for future reference and continuous improvement.

9. Explain a time when you had to work under pressure to complete a critical repair and how you managed the situation.

During a critical system outage, the main database server failed, taking down our e-commerce platform. The pressure was immense because every minute of downtime meant lost revenue and frustrated customers. My role was to diagnose the issue and restore the database as quickly as possible. First, I quickly assessed the situation, identifying the hardware failure as the root cause. I then coordinated with the hardware team to expedite the replacement of the failed component.

While the hardware was being replaced, I prepared a backup server with the latest database snapshot. I also scripted the necessary configuration changes to point the application servers to the backup database. Once the hardware replacement was complete, I restored the latest database backup to the replacement server. I validated the data integrity and performed thorough testing before switching over the application servers. By prioritizing tasks, coordinating effectively, and proactively preparing for different scenarios, I successfully restored the database service within the agreed upon SLA, minimizing the impact of the outage.

10. How do you approach a situation where you identify a potential safety hazard on the job site?

My primary concern is always safety. If I identify a potential hazard, my immediate action is to inform my supervisor or the designated safety personnel. I would also take steps to mitigate the risk, if it is safe for me to do so, such as cordoning off the area or providing a warning sign.

I would then document the hazard, its location, and the steps taken to address it. This ensures that the issue is properly tracked and resolved to prevent future incidents. I understand the importance of proactive hazard identification and reporting to maintain a safe working environment for everyone.

11. Describe your experience with different types of bearings and lubrication methods.

My experience with bearings includes working with ball bearings, roller bearings (cylindrical and tapered), and journal bearings. I understand the basic principles behind each, including how ball and roller bearings use rolling elements to reduce friction, while journal bearings rely on a fluid film for lubrication. I've also encountered thrust bearings designed to handle axial loads. I have practical exposure through maintaining equipment, replacing worn bearings, and performing basic troubleshooting.

Regarding lubrication, I'm familiar with grease lubrication, oil bath lubrication, and forced oil lubrication systems. I understand the importance of selecting the correct lubricant based on operating conditions (speed, load, temperature). I have hands-on experience with grease guns for manual lubrication and have worked with systems that automatically dispense lubricant at specified intervals. I've also been involved in monitoring lubricant condition and performing oil analysis to identify potential bearing issues.

12. What methods do you use to inspect equipment for wear and tear, and how do you document your findings?

I use a combination of visual inspection, tactile checks, and specialized tools, depending on the equipment. Visual inspection involves looking for obvious signs of wear like cracks, corrosion, or deformation. Tactile checks include feeling for looseness, excessive play, or unusual vibrations. For documentation, I use a standardized checklist or inspection form, noting the date, equipment ID, specific observations (e.g., "crack on housing near bolt #3"), severity level (e.g., "minor," "moderate," "severe"), and any immediate actions taken or recommendations for repair. Photos are included where appropriate.

My findings are documented immediately after the inspection in a digital format, usually a spreadsheet or database. This includes a clear description of the wear and tear, its location, and severity. Furthermore, a maintenance request or work order is generated and attached to the equipment's record, tracking the issue from identification to resolution. The completed documentation is then stored in a central, accessible location for future reference and trending analysis.

13. Can you provide an example of a time when you had to reverse engineer a part that was no longer available?

In a previous role at a robotics startup, we relied on a specific sensor module for obstacle avoidance. The manufacturer unexpectedly discontinued the module, leaving us without a readily available replacement. To keep our project on track, I took on the task of reverse engineering the sensor.

I started by carefully disassembling the module, documenting each component and its connections. I then used a multimeter and oscilloscope to trace the circuit and understand the signal flow. Through this process, I identified the key components and their functions. Finally, I recreated a functional equivalent using readily available components and a microcontroller, programming it to mimic the original module's behavior. This allowed us to continue development without significant delays.

14. Explain your understanding of vibration analysis and how it can be used to diagnose equipment problems.

Vibration analysis is a process of measuring and analyzing the vibration signatures of machines and equipment to identify potential faults or anomalies. Each component within a machine vibrates at specific frequencies and amplitudes. By using sensors to detect these vibrations and analyzing the frequency spectrum, we can pinpoint the source of excessive vibration or unusual patterns. For example, an imbalance in a rotating component will show up as a peak at the rotational frequency, while bearing defects may cause peaks at specific bearing defect frequencies.

This technique allows for proactive maintenance by diagnosing issues like misalignment, imbalance, looseness, bearing failures, gear problems, and cavitation before they lead to catastrophic failures or costly downtime. It enables condition-based maintenance, where maintenance is performed only when needed, based on the actual condition of the equipment, rather than on a predetermined schedule. This leads to increased efficiency and reduced maintenance costs.

15. How do you ensure accurate measurements and tolerances when fabricating or repairing parts?

Ensuring accurate measurements and tolerances involves a multi-faceted approach. First, I'd select calibrated measuring tools appropriate for the required precision (e.g., calipers, micrometers, gauges). Regular calibration checks are crucial. Then, I'd carefully follow established procedures for taking measurements, minimizing parallax and other potential errors. Multiple measurements are taken and averaged. For fabrication, using CNC machines or other automated processes helps maintain tight tolerances. For repairs, I'd prioritize matching the original part's dimensions and tolerances, referencing technical drawings or using reverse engineering techniques when necessary. Finally, the finished part is inspected thoroughly using appropriate measurement tools and techniques to verify that it meets the required specifications.

16. Describe a situation where you had to train or mentor a less experienced millwright.

I once mentored a new apprentice millwright who was struggling with precision alignment. I started by explaining the theoretical principles behind proper alignment, emphasizing minimizing vibration and extending machine lifespan. Then, I demonstrated the practical application using laser alignment tools on a pump assembly. I walked him through each step: setting up the laser, taking initial readings, interpreting the data, and making the necessary adjustments to shims and couplings. I emphasized the importance of documenting each adjustment and double-checking the results.

Throughout the process, I provided constructive feedback and encouraged him to ask questions. I also shared some tricks I'd learned over the years for troubleshooting common alignment issues. We worked together until he felt comfortable performing the alignment independently. I also quizzed him on identifying wear patterns on couplings as those are a sign that alignment needs adjustment.

17. What is your experience with reading and interpreting blueprints, schematics, and technical manuals?

I have experience reading and interpreting blueprints, schematics, and technical manuals throughout my career. I can understand the layout and components represented in blueprints, identify connections and signal flow in schematics, and extract necessary information from technical manuals. I'm comfortable with interpreting symbols, abbreviations, and technical jargon commonly used in these documents.

For example, I've used blueprints to understand architectural plans for server room build-outs, schematics to debug electronic circuits, and technical manuals to configure network devices and troubleshoot software issues. My approach involves carefully studying the document, identifying key components and their relationships, and cross-referencing information as needed to build a complete understanding.

18. How do you prioritize tasks when faced with multiple repair requests?

When faced with multiple repair requests, I prioritize based on several factors: severity, impact, urgency, and dependencies. Severity refers to the level of disruption the issue causes (e.g., critical system outage vs. minor UI bug). Impact considers how many users or systems are affected. Urgency depends on deadlines or Service Level Agreements (SLAs). Dependencies highlight if resolving one issue is required before addressing others.

I typically use a matrix to rank requests:

- Critical/High Impact/Urgent: Immediate attention.

- Medium Impact/Urgent or Critical/Low Impact: High priority.

- Low Impact/Low Urgency: Scheduled for later.

I'd also consider the effort required to resolve each issue. A quick fix for a high-impact problem might be prioritized over a complex fix for a low-impact problem. Finally, clear communication with stakeholders about timelines and priorities is essential. If required, I will escalate appropriately.

19. Describe your experience with using laser alignment tools.

I have hands-on experience with laser alignment tools for ensuring precise machinery setup and maintenance. I've used these tools, including both reflectorless and reflected beam types, to align shafts, pulleys, and rollers in industrial settings. My experience includes identifying and correcting misalignment issues such as offset, angularity, and twist, resulting in reduced vibration, improved equipment lifespan, and enhanced operational efficiency.

Specifically, I'm familiar with interpreting laser alignment data, understanding tolerances, and implementing corrective actions, such as shimming and adjusting equipment positions, based on the measurements obtained. I have also documented alignment procedures and results, contributing to preventative maintenance programs.

20. How do you handle working in confined spaces or at heights?

When working in confined spaces or at heights, safety is my top priority. I strictly adhere to all relevant safety regulations and procedures, including conducting thorough risk assessments before starting any work. This involves identifying potential hazards, implementing appropriate control measures, and ensuring I have the necessary personal protective equipment (PPE), such as harnesses, respirators, and fall protection gear, and that all are inspected prior to use.

I also maintain clear communication with my team or supervisor and ensure that rescue plans are in place in case of an emergency. I am comfortable participating in safety training and briefings, and I proactively identify and report any potential hazards I observe during work. I understand the importance of proper ventilation in confined spaces and the need for fall protection systems at heights. My goal is always to complete tasks safely and efficiently while minimizing any risk to myself or others.

21. What steps do you take to ensure a safe and clean work environment?

I prioritize a safe and clean work environment by consistently practicing good housekeeping. This includes promptly cleaning up spills, properly disposing of waste, and ensuring walkways are free of obstructions. I also adhere to all safety guidelines and procedures provided by the company, including wearing appropriate personal protective equipment (PPE) when necessary and reporting any hazards or unsafe conditions I observe to the appropriate personnel.

Furthermore, I actively participate in safety training programs and stay informed about relevant safety regulations and best practices. If I notice a potential safety risk, I take immediate action to mitigate it, either by correcting the issue myself (if possible and safe to do so) or by reporting it to a supervisor or safety representative. I believe that a safe and clean environment is everyone's responsibility, and I'm committed to contributing to it.

Millwright interview questions for experienced

1. Describe a time you diagnosed a complex machine failure and the steps you took to resolve it.

During my time at a manufacturing plant, a critical conveyor system halted production. Initial checks revealed no immediately obvious issues like tripped breakers or visible damage. The control panel displayed a generic 'System Fault' error.

My troubleshooting involved these steps: 1) Examined PLC logs: I downloaded and analyzed the Programmable Logic Controller (PLC) logs. This revealed a pattern of intermittent communication errors between the main PLC and a remote I/O module controlling a specific motor. 2) Isolating the issue: I systematically disconnected components starting with the motor identified by the I/O module. After swapping the suspected I/O module, the conveyor system restarted. The fault was traced to a faulty I/O module which was subsequently replaced. This avoided lengthy downtime.

2. Walk me through your experience with different types of rigging and hoisting equipment.

My experience with rigging and hoisting equipment includes hands-on use and theoretical understanding gained through projects and training. I've worked with chain falls, lever hoists (come-alongs), and electric chain hoists, understanding their safe working loads (SWL) and inspection criteria. I am familiar with different types of slings, including wire rope, synthetic web slings, and chain slings, and how to select the appropriate sling based on load weight, shape, and environmental conditions. I have also experience inspecting each of these to ensure that they are fit for operation.

3. How have you ensured safety compliance during complex millwright projects?

Safety compliance on complex millwright projects is paramount. I ensure it through a multi-faceted approach. First, I conduct thorough risk assessments and hazard analyses before any work begins, documenting potential dangers and mitigation strategies. This includes reviewing lock-out/tag-out procedures, confined space entry protocols, and fall protection plans.

Next, I enforce strict adherence to safety protocols through regular toolbox talks and pre-job briefings. I also conduct routine site inspections to identify and correct any unsafe conditions immediately. All personnel are empowered to stop work if they observe a safety violation, and I actively promote a culture of safety where reporting concerns is encouraged and acted upon promptly. Finally, I ensure all team members have the appropriate certifications and training for the tasks they perform. This may include rigging, welding, or operating heavy machinery.

4. Elaborate on your experience with vibration analysis and its impact on machine maintenance.

My experience with vibration analysis primarily involves using it for predictive maintenance on rotating equipment such as pumps, motors, and gearboxes. I've utilized tools like FFT analyzers and accelerometers to collect vibration data, which is then analyzed to identify potential faults such as imbalance, misalignment, bearing defects, and looseness. By trending vibration data over time, I can detect developing issues early on, allowing for proactive maintenance planning.

The impact of vibration analysis on machine maintenance has been significant. By identifying and addressing problems before they lead to catastrophic failures, we've been able to reduce downtime, lower maintenance costs, and extend the lifespan of critical equipment. For example, identifying a developing bearing fault in a large motor allowed us to schedule a bearing replacement during a planned shutdown, avoiding a costly unscheduled outage. Furthermore, vibration analysis has helped optimize maintenance schedules, moving from reactive or calendar-based approaches to a condition-based maintenance strategy.

5. What types of preventative maintenance programs have you developed or improved?

I've developed and improved preventative maintenance programs focusing on both time-based and condition-based maintenance strategies. For time-based programs, I've created schedules for routine inspections, lubrication, filter changes, and component replacements based on manufacturer recommendations and historical data. I've also implemented condition-based maintenance programs using sensor data and predictive analytics to identify potential equipment failures before they occur, leading to more efficient maintenance and reduced downtime.

Specifically, I've worked with vibration analysis, thermal imaging, and oil analysis to monitor equipment health. I developed a system that would track equipment metrics and flag any anomalies that were out of the ordinary. This system provided a comprehensive overview of the health of our machines and when maintenance should be scheduled.

6. Tell me about a challenging alignment project you completed and the tools you used.

In my previous role, I worked on aligning a large dataset of product descriptions scraped from various e-commerce sites with our internal product catalog. This was challenging because the scraped data had inconsistencies in naming conventions, typos, and missing attributes. The project aimed to improve search relevancy and product recommendations on our platform.

To tackle this, I used a combination of tools and techniques. Specifically, I leveraged Python with libraries like pandas for data manipulation, fuzzywuzzy for fuzzy string matching to handle variations in product names, and spaCy for natural language processing to extract key attributes. I also created a custom rule-based system to standardize the scraped data based on domain-specific knowledge and used regular expressions extensively for data cleaning and transformation. We ultimately achieved a significant improvement in data quality and search accuracy as a result of this alignment project.

7. How do you handle working under pressure and meeting tight deadlines?

When facing pressure and tight deadlines, I prioritize tasks by assessing their urgency and importance. I break down large projects into smaller, manageable steps to avoid feeling overwhelmed. I then focus on completing the most critical tasks first. Effective time management is key, and I utilize tools like calendars and to-do lists to stay organized.

Maintaining clear communication with the team and stakeholders is also crucial. I proactively inform them of my progress, potential roadblocks, and any necessary adjustments to the timeline. If necessary, I don't hesitate to ask for help or delegate tasks to ensure we meet the deadline. I also make sure to take short breaks to avoid burnout and maintain focus.

8. Give an example of a time when you had to train or mentor junior millwrights.

During a large plant shutdown, several newly-hired millwrights were assigned to my team to assist with equipment overhauls. I took the initiative to mentor them on proper bearing installation techniques. This involved demonstrating the use of precision measuring tools like dial indicators and micrometers to ensure accurate alignment and tolerances. I also explained the importance of using correct lubrication and torquing procedures to prevent premature bearing failure.

Specifically, one junior millwright struggled with interpreting bearing manufacturer specifications. I walked him through several examples, showing him how to decipher the codes and identify the correct preload settings. We then worked together on a pump rebuild, where he was able to apply what he learned under my direct supervision. By the end of the shutdown, all the junior millwrights showed significant improvement in their understanding of bearing maintenance best practices and were able to perform tasks more confidently and efficiently.

9. What are your experiences with hydraulic and pneumatic systems, specifically troubleshooting?

I have hands-on experience troubleshooting both hydraulic and pneumatic systems, primarily within [mention industry or application, e.g., manufacturing and automated machinery]. My experience includes diagnosing issues such as pressure drops, leaks, and component failures using tools like pressure gauges, flow meters, and visual inspections. I am familiar with reading hydraulic and pneumatic schematics to trace circuits and identify potential problem areas.

Specifically, I've addressed common problems like malfunctioning valves (solenoid and directional), cylinder seal failures, and pump cavitation. My approach generally involves isolating the problem component, verifying proper power and signal inputs, and then either repairing or replacing the faulty part. In pneumatics, I've worked on issues related to air compressors, regulators, and actuators, focusing on maintaining optimal air quality and pressure levels. I am also comfortable with safely bleeding pressure from hydraulic and pneumatic systems.

10. Describe your experience interpreting blueprints, schematics, and technical manuals.

Throughout my career, I've frequently interpreted blueprints, schematics, and technical manuals across various projects. For example, in a past role involving electrical systems, I used wiring schematics to troubleshoot issues, identify faulty components, and implement necessary repairs. I also consulted technical manuals to understand the specifications and operating procedures for new equipment, ensuring proper installation and maintenance.

I'm comfortable extracting key information from these documents, such as dimensions, tolerances, material specifications, and assembly instructions. My approach involves carefully reviewing the document, breaking down complex diagrams into simpler components, and cross-referencing information to ensure accuracy. When facing ambiguity, I proactively seek clarification from subject matter experts to avoid potential errors.

11. How have you used technology to improve the efficiency of your work?

I consistently leverage technology to optimize my workflow. For instance, I use project management tools like Asana or Jira to track tasks, deadlines, and dependencies, fostering better organization and collaboration. Furthermore, I automate repetitive tasks using scripting languages like Python or Bash. For example, I wrote a Python script to automate the generation of daily reports, which previously took several hours of manual data consolidation.

Another significant improvement came from adopting cloud-based collaboration tools such as Google Workspace or Microsoft Teams. This facilitated real-time communication and document sharing, minimizing delays and version control issues. Also, I often use code completion and linting tools like ESLint or PyLint to minimize errors, speed up development, and improve code quality, allowing me to focus on more complex challenges.

12. What is your approach to continuous learning and staying up-to-date with industry advancements?

I prioritize continuous learning through a multi-faceted approach. I regularly read industry blogs, tech news sites, and follow key influencers on social media to stay informed about emerging trends and technologies. I also actively participate in online communities and attend webinars or online conferences to learn from experts and peers.

Furthermore, I dedicate time to hands-on practice and experimentation. I might explore new libraries, frameworks, or tools by working on personal projects or contributing to open-source initiatives. This practical application solidifies my understanding and allows me to adapt to new advancements more effectively. If it's programming related, I would actively practice leetcode questions and use platforms like Coursera and Udemy to dive deeper into a certain technology. For example:

import tensorflow as tf

model = tf.keras.Sequential([

tf.keras.layers.Dense(10, activation='relu', input_shape=(784,)),

tf.keras.layers.Dense(10, activation='softmax')

])

13. Explain your experience with laser alignment techniques and when they are most effective.

My experience with laser alignment primarily involves using laser trackers and total stations for aligning machinery and equipment in industrial settings. I've used these tools to ensure that components are precisely positioned according to engineering specifications. The process typically involves setting up the laser, establishing a coordinate system, taking measurements of target points on the components to be aligned, and then comparing these measurements to the design coordinates. Adjustments are made to the components until they fall within the specified tolerances. Software is then used to document results.

Laser alignment techniques are most effective when high precision is required, when dealing with large or complex machinery, or when traditional mechanical methods are impractical or time-consuming. Specific scenarios include aligning shafts in rotating equipment (pumps, motors, turbines), aligning rolls in paper mills or printing presses, and aligning structural components in construction or manufacturing. Also when accessibility is difficult for conventional alignment tools.

14. Describe a time you identified a potential safety hazard and how you addressed it.

During a previous internship at a construction site, I noticed that several workers were not consistently wearing their safety goggles while operating power tools, especially grinders. This posed a significant risk of eye injuries from flying debris. I brought this concern to the attention of my supervisor, explaining the potential consequences of not wearing proper eye protection.

To address the issue, I suggested a few measures. First, I proposed a reminder campaign involving clear and visible posters near the tool storage area and work zones, emphasizing the mandatory use of safety goggles. Second, I suggested that the supervisor conduct brief toolbox talks before each shift to reinforce safety protocols and address any questions or concerns workers might have. Finally, I recommended that the supervisor perform periodic checks to ensure compliance with safety regulations, providing immediate feedback and corrective action as needed. My supervisor implemented these suggestions, and the consistent use of safety goggles significantly improved within a few days.

15. What is your experience with predictive maintenance technologies?

I have experience with predictive maintenance technologies through various projects and learning initiatives. I've worked with time-series data analysis using Python libraries like Pandas and NumPy to identify patterns and anomalies indicative of potential equipment failures. This includes using techniques like moving averages, exponential smoothing, and ARIMA models to forecast future equipment performance.

Furthermore, I've explored machine learning models such as Support Vector Machines (SVMs) and Random Forests for classifying equipment health based on sensor data. I've also investigated deep learning approaches, particularly Recurrent Neural Networks (RNNs) and LSTMs, for sequence-based predictive maintenance, using historical sensor readings to predict remaining useful life (RUL). I'm familiar with utilizing cloud platforms like AWS and Azure for deploying and scaling predictive maintenance solutions, including services like AWS IoT and Azure IoT Hub for data ingestion and processing. I have also researched use of vibration analysis, oil analysis and thermal imaging in combination with machine learning techniques to improve predictive accuracy.

16. Tell me about your experience in equipment installation.

My experience in equipment installation spans several years, focusing on both hardware and software aspects. I've installed and configured various types of equipment, including network devices (routers, switches), servers (physical and virtual), and specialized scientific instruments. This often involves tasks like unpacking, physically mounting equipment, connecting power and network cables, and performing initial configuration.

Specifically, I've worked with installing and configuring rack servers, ensuring proper cabling and power distribution. I also have experience with operating system installations (Windows Server, Linux), driver updates, and software deployments. Furthermore, I am familiar with creating detailed installation documentation and troubleshooting common installation issues.

17. What is your experience with root cause failure analysis?

I have experience with root cause failure analysis (RCFA) in several contexts. I've used methodologies like the 5 Whys, fishbone diagrams (Ishikawa diagrams), and Pareto analysis to identify the underlying causes of problems. My experience includes identifying software bugs, hardware malfunctions, and process inefficiencies. I can analyze data from logs, metrics, and incident reports to pinpoint the source of a failure.

For example, I've used git bisect to locate the specific commit introducing a bug, and I've implemented monitoring and alerting systems to proactively detect anomalies that could lead to failures. I am familiar with creating RCA reports that document the problem, the analysis process, the root cause, and recommended corrective actions.

18. How do you prioritize tasks in a fast-paced environment?

In a fast-paced environment, I prioritize tasks using a combination of urgency, importance, and impact. I start by quickly assessing all incoming tasks and categorizing them based on these factors. I use techniques like the Eisenhower Matrix (urgent/important) to visualize priorities. For example, if a critical bug impacting production is reported, it immediately becomes the top priority due to its high urgency and impact.

Beyond the initial assessment, I maintain flexibility and regularly re-evaluate priorities as new information arises or deadlines shift. This includes communicating with stakeholders to clarify expectations and dependencies, and adjusting my workflow accordingly. I am proactive in identifying potential roadblocks and escalating issues early to minimize disruptions. If I have too many high priority items, I will push to delay less important items, delegate or ask for additional help.

19. Describe your experience working with computerized maintenance management systems (CMMS).